At its Heilbronn site, TSR Recycling GmbH uses data-based analyses from Bosch Rexroth to avoid potential downtime costs. The moderate fees for the CytroConnect digital service can quickly recoup themselves.

Recycling companies are highly depending on the availability of their equipment. If hydraulically driven shredders, scrap shears or presses fail, there is a risk of severe penalties. If trucks, trains or ships wait in vain for their cargo, the follow-up costs can climb into five to six figures. To prevent this, TSR Recycling GmbH is breaking new ground with the digital service CytroConnect PREDICT from Bosch Rexroth. The rule- and data-based analyses using machine learning can not only prevent production downtimes, but also reduce maintenance costs and extend the service life of the equipment.

At its Heilbronn site, TRS Recycling GmbH processes scrap metal and iron.

Established in 1890, TSR Recycling is based in Lünen in North Rhine-Westphalia and employs 4,100 people around the world. The company's successes include annual savings of 12 million tons of iron ore, 5 million tons of coal and 8 million tons of CO₂. The company processes ferrous and non-ferrous metals at its German site in Heilbronn. “The output and purity of our products can be further improved only with a high degree of innovation along the entire process chain can,” explained Sebastian Bischof, Technical Manager in the Shears and Presses division. “The predictive analysis and maintenance of our production machines plays a central role here.”

With a premise of finding the most energy-efficient solution possible that minimizes both CO₂ emissions and production costs, TSR Recycling opted for a predictive analytics solution from its long-standing hydraulics partner Bosch Rexroth. “After a detailed market analysis, the overall package from Bosch Rexroth won us over,” said Sebastian Bischof.

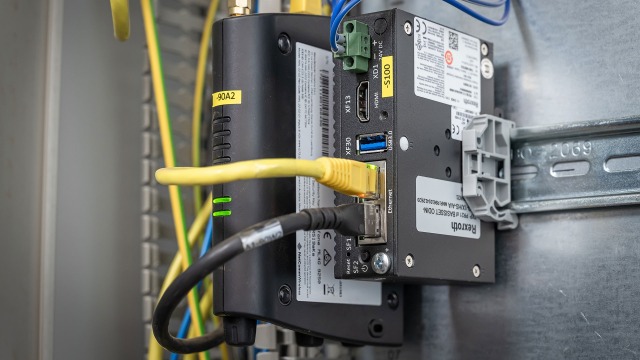

A pair of scrap shears from Metso was the first machine at TSR to be prepared for data analysis. The inventory and the necessary hardware update were carried out by Hydrobar, a Rexroth Certified Excellence Partner based in Sindelfingen. The company equipped the process-critical system parts with suitable sensors and installed a DAQ box (data acquisition) with an integrated gateway. This records sensor data which are then pre-processed by the IoT Gateway and transferred in encrypted form to a cloud. Here, the data streams are verified, decrypted and evaluated with the help of self-learning algorithms.

If the measurements deviate significantly from the learned comparison data, the system recognizes an anomaly and reports it to the supervising expert team at Rexroth. The experts verify the situation and make a predictive maintenance recommendation to those responsible at TSR. The recycling company then has enough time to plan and prepare the measure without productivity suffering. By recognizing and correction anomalies early on, damage and unplanned downtimes can be avoided.

Scrap shears are among the production-critical systems. Rule and data-based analyses should help to avoid high downtime costs.

Straightforward hardware update: DAQ box with integrated gateway from Bosch Rexroth for collecting data and transmitting them securely to a cloud.

There was a four-week learning phase before operations started in August 2021. During this phase, the analytics team at Bosch Rexroth first identified suitable models and parameters for the scrap shears. The algorithms selected for the analysis are improved on an ongoing basis, as a result of which the predictions become more and more accurate over time.

“Predictive analyses require a high degree of expertise and a comprehensive neural network which processes huge quantities of data from a giant pool of anonymous comparative data,” explained Marcello Miceli, Senior Manager Service Sales Support at Bosch Rexroth. “It’s virtually impossible for companies to set up such a solution on their own, but as a rental service predictive analytics becomes attractive for many users.”

Marcello Miceli knows from experience that for most failure-critical hydraulic applications CytroConnect PREDICT pays for itself within the first year. How much the failure of a hydraulic component actually costs depends on how long it takes to procure spare parts. “Generally speaking, the avoided downtime costs exceed the monthly fees by a factor of five or more,” said the Rexroth expert. “If just one or two downtimes a year are avoided, the technical investments will have paid for themselves within a few weeks or months. The peripheral costs should also be borne in mind. For example, damage to other components can be avoided by monitoring the oil cleanliness.”

The Predictive Maintenance Team at Bosch Rexroth then evaluates the machine learning data and gives maintenance recommendations.

Predictive analytics in recycling prevents unplanned downtimes, reduces maintenance work and extends equipment uptime. The data can also help to improve production on an ongoing basis.

It is still too early for TSR in Heilbronn to draw a final conclusion on cost and energy savings. However, Sebastian Bischof already has one or two successes to report: “With the newly introduced system, we were able to identify several failure-critical anomalies early on. For example, worn valves would have disrupted production in the foreseeable future. We’ve achieved our main goal,” said the technical manager. “Predictive maintenance protects against unplanned downtimes and also helps us to minimize maintenance costs at the Heilbronn site. Because certain hydraulic components are no longer replaced on a regular basis, in certain cases excessively early, the maintenance staff have much less work to do. This also helps to alleviate the shortage of skilled workers. At the same time, condition information and predictions increase energy efficiency and equipment uptime, which in turn saves money.” CytroConnect PREDICT monitors not only the cylinders, the pumps and the motors in the scrap shears but also the cleanliness of the hydraulic oil and the tank parameters.

Sebastian Bischof is also hoping to improve production further with the data obtained. “By assigning specific hydraulic data to particular scrap types, we’re able to analyze and adjust processes. We’re very happy with the result because of these many benefits too,” said Sebastian Bischof. “If this extremely positive impression proves correct, we’ll retrofit further production systems with the predictive maintenance system from Bosch Rexroth.”