The future of Hydraulics

Connected Hydraulics will leverage the power and intelligence of Bosch Rexroth’s advanced hydraulics technology to break through limits and set new benchmarks for performance, functionality and lifetime.

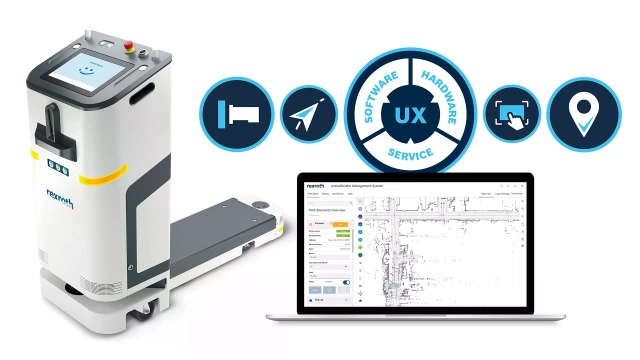

At Bosch Rexroth, our vision for factory automation offers complete variability. The walls, the floor, the ceiling will all be fixed, but everything else will be mobile. Assembly lines will be modular, and their constituent machines will move and reorganize themselves into new lines for new purposes.

The Bosch Rexroth Regional Training Center (BRRTC) was established to drive the adoption of advanced manufacturing technologies in the new Jurong Innovation District (JID).

If movement is central to what you do, it’s the very core of what we do. Every aspect of a Hägglunds solution – from our hydraulic drive systems to the knowledge and support we integrate with them – delivers and protects the motion you depend on.

ctrlX AUTOMATION surmounts the classic boundaries between machine controls, the IT world and the Internet of Things. Find out for yourself why ctrlX AUTOMATION is an significant solution for your factory of the future.