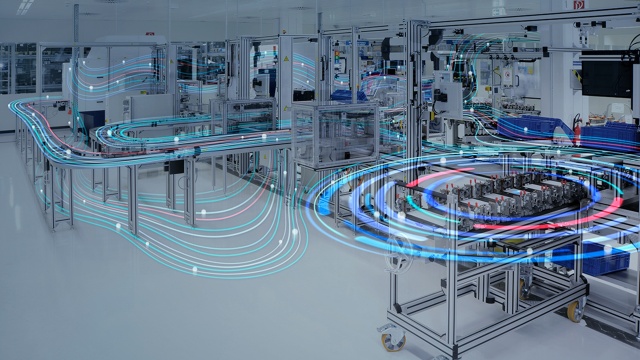

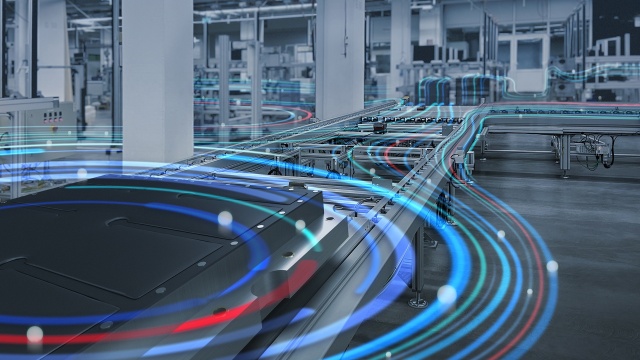

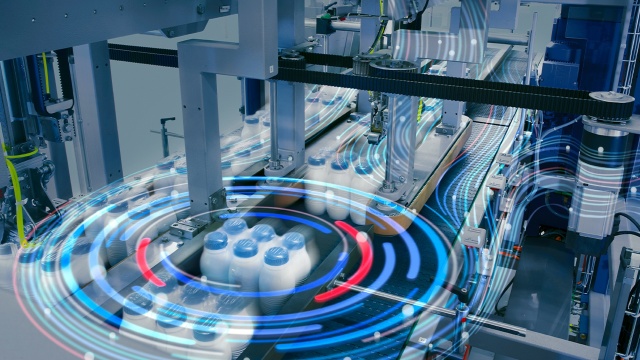

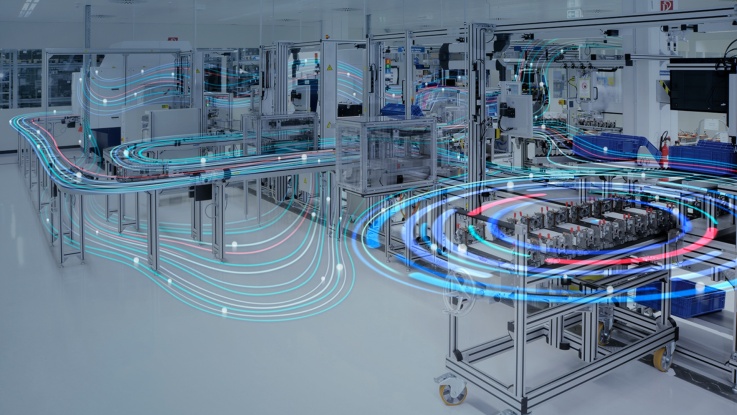

Open for Scalability.

That’s complete factory automation.

Move battery manufacturing forward – fast

From pacemakers to smartphones to EVs, the electric battery has become undeniably essential to modern life. Battery manufacturers are seeking smart, adaptable manufacturing solutions to help solve complex process challenges and stay flexible as battery technology develops and demand surges.

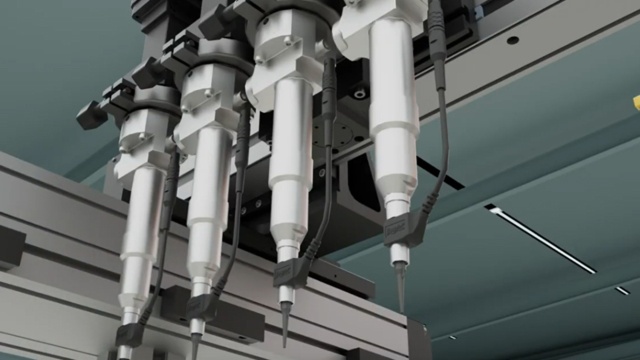

Bosch Rexroth is ready to meet those challenges, combining deep battery manufacturing expertise with complete factory automation solutions, tailored to meet complex battery production requirements (heavy loads, clean room/dry room conditions, no metal or copper, etc.).

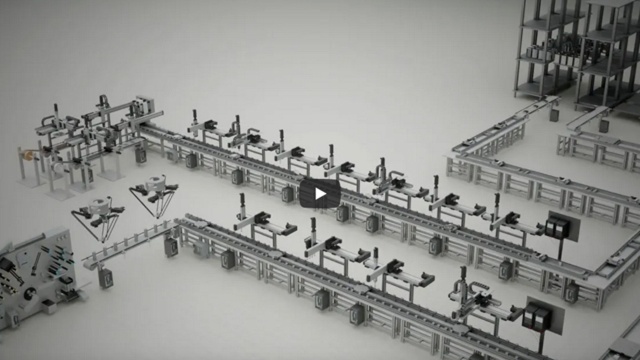

Our portfolio of innovative, flexible and complete production solutions enables battery manufacturers to get to market faster through cross-technology production systems that target key manufacturing steps, such as electrode and cell production, battery module and pack assembly stations and end-of-line testing.

Industry-leading portfolio to supercharge battery production

Factory of the Future Roadshow