Open for Transformation.

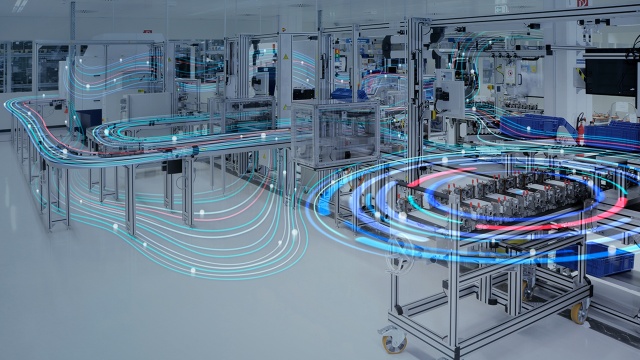

That’s complete factory automation.

Complete automation solutions to revolutionize your EV manufacturing

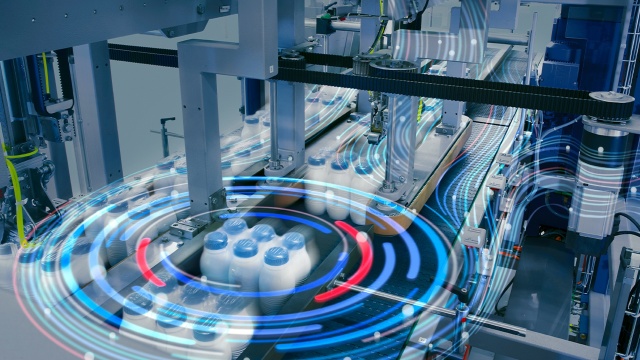

Electric vehicle (EV) manufacturers strive every day to solve quality and throughput challenges common to all vehicle assembly operations, as well as streamline how complex battery packs and e-axles are incorporated into these processes in ways that can accelerate their production and meet market demand.

Bosch Rexroth has the transformative technology portfolio and vehicle assembly system experience to help solve those challenges today. Bosch Rexroth’s complete factory automation portfolio combines innovative controls, full mechatronics, state-of-the-art conveyor systems and advanced assembly and linear technologies into high-performance material transport and assembly automation solutions.

This uniquely equips us to create solutions tailor-made to solve the complex scale-up, throughput and supply chain challenges the EV industry faces.