Rethinking welding technology. With the PRC7000 welding control, you can master any challenge

Welding control system PRC7000 – Why you can count on us for resistance welding

Sustainable and decisive competitive advantages – that is what you will gain from our solutions. We pride ourselves in developing holistic and state-of-the-art systems for resistance spot welding. And such solutions can only be found by consistently questioning the status quo.

Take your welding systems to the next level

Master every challenge with confidence with the future-oriented and scalable solution portfolio for resistance spot welding from Bosch Rexroth. Our welding controls and medium frequency welding transformers make a decisive difference for you – in terms of performance and efficiency:

Sounds too good to be true? Living proof: PRC7000

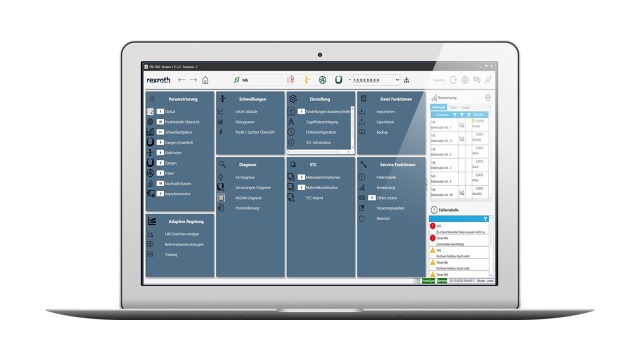

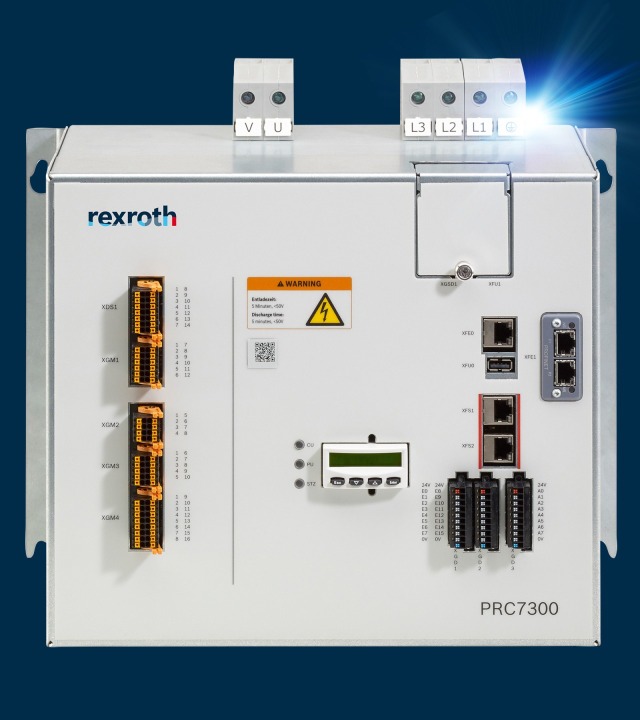

Weld quality to the point: With the new, powerful welding control PRC7000, perfect weld spots finally become reproducible. What else makes it so indispensable and future-proof? Adaptive controls and flexible programmability allow for different sheet thickness combinations and material mixes – from steel to aluminum – to be easily processed. The integrated IoT connector, which provides structured data for central processing, quality control and technology data management, makes PRC7000 ready for Industry 4.0

The comprehensive and future-proof portfolio for resistance welding

Discover the technologically leading welding controls and medium frequency welding transformers from Bosch Rexroth.