Cancel

确定

China中文

选择您的位置

International

选择您的位置

Directional spool valves, direct operated, with solenoid actuation – Type WE 6...E

咨询留言

产品型号

WE

6

6X

/

E

Result count

3498 的 3498

Main ports

3

3 main ports

4

4 main ports

Type

Directional valve

WE

Directional valve

Size

Size 6

6

Size 6

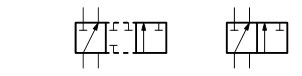

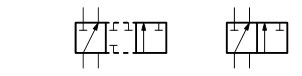

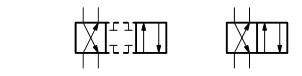

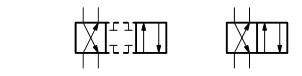

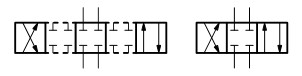

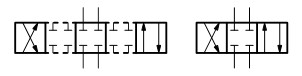

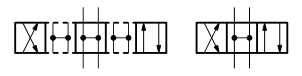

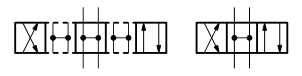

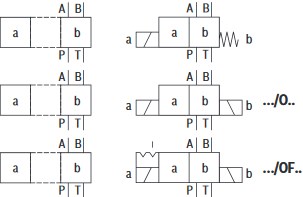

Symbol

A

C

D

B

Y

E

F

G

H

J

L

M

P

Q

R

T

U

V

W

Series

Series 60 … 69

6X

Series 60 … 69

Spring return / detent

With spring return

O

Without spring return

OF

Without spring return with detent

Solenoid version

High-power solenoid, wet-pin, with detachable coil

E

High-power solenoid, wet-pin, with detachable coil

Solenoid voltage

G110

Direct voltage 110 V

G12

Direct voltage 12 V

G125

Direct voltage 125 V

G180

Direct voltage 180 V

G205

Direct voltage 205 V

G220

Direct voltage 220 V

G24

Direct voltage 24 V

G26

Direct voltage 26 V

G48

Direct voltage 48 V

G96

Direct voltage 96 V

W100

AC voltage 100 V 50/60 Hz

W110

AC voltage 110 V 50/60 Hz

W110R

DC solenoid with rectifier for AC voltage

W120

AC voltage 120 V 50/60 Hz

W200

AC voltage 200 V 50 Hz

W230

AC voltage 230 V 50/60 Hz

Manual override

Without manual override

N

With manual override

N2

With manual override "mushroom button" (small)

N4

With lockable manual override "mushroom button" (small)

N5

With lockable manual override "mushroom button" (large)

N6

With manual override "mushroom button" (large), not lockable

N7

With lockable manual override "nut"

N9

With concealed manual override (standard)

Corrosion resistance

None (valve housing primed)

J3

Improved corrosion protection (240 h salt spray test according to EN ISO 9227

J5

High corrosion protection (720 h salt spray test according to EN ISO 9227)

Electrical connection

K4

Connector 3-pole (2 + PE) according to DIN EN 175301-803 (Standard)

K4K

Connector 3-pole (2 + PE) according to DIN EN 175301-803 With potted-in plug base and sealing element

K40

Connector 2-pole, DT04-2PA (Deutsch type)

K72L

Connector, 4-pole, M12x1 according to DIN EN 61076-2-101 with suppressor diode, coding A

K73L

Connector, 4-pole, M12x1 according to DIN EN 61076-2-101 with suppressor diode, coding A (Standard)

C4

Connector 2-pole (Junior-Timer type)

Spool position monitoring

Without position switch

QMAG24

Inductive position switch type QM: Monitored spool position „a″

QMBG24

Inductive position switch type QM: Monitored spool position „b″

QR0G24S

Inductive position switch type QR: Monitored rest position

QRABG24E

Inductive position switch type QR: Monitored spool position "a" and "b"

QSAG24W

Inductive position switch type QS: Monitored spool position „a″

QSBG24W

Inductive position switch type QS: Monitored spool position „b″

QS0G24W

Inductive position switch type QS: Monitored spool position „0“

QSABG24W

Inductive position switch type QS: Monitored spool position „a“ and „b“

Additional options

Without additional options

/

With additional options

Switching time increase

Without switching time increase

A12

With switching time increase

Throttle insert port A

Without throttle insert

H08

Throttle Ø 0,8 mm [0.031 inch]

H10

Throttle Ø 1,0 mm [0.039 inch]

H12

Throttle Ø 1,2 mm [0.047 inch]

H15

Throttle Ø 1,5 mm [0.059 inch]

H20

Throttle Ø 2,0 mm [0.079 inch]

H25

Throttle Ø 2,5 mm [0.098 inch]

Throttle insert port B

Without throttle insert

R06

Throttle Ø 0,6 mm [0.024 inch]

R08

Throttle Ø 0,8 mm [0.031 inch]

R10

Throttle Ø 1,0 mm [0.039 inch]

R12

Throttle Ø 1,2 mm [0.047 inch]

R15

Throttle Ø 1,5 mm [0.059 inch]

R20

Throttle Ø 2,0 mm [0.079 inch]

R25

Throttle Ø 2,5 mm [0.098 inch]

R30

Throttle Ø 3,0 mm [0.120 inch]

R40

Throttle Ø 4,0 mm [0.160 inch]

Throttle insert port A and B

Without throttle insert

N06

Throttle Ø 0,6 mm [0.024 inch]

N08

Throttle Ø 0,8 mm [0.031 inch]

N10

Throttle Ø 1,0 mm [0.039 inch]

N12

Throttle Ø 1,2 mm [0.047 inch]

N15

Throttle Ø 1,5 mm [0.059 inch]

N20

Throttle Ø 2,0 mm [0.079 inch]

N30

Throttle Ø 3,0 mm [0.120 inch]

Throttle insert port T

Without throttle insert

X06

Throttle Ø 0,6 mm [0.024 inch]

X08

Throttle Ø 0,8 mm [0.031 inch]

X10

Throttle Ø 1,0 mm [0.039 inch]

X12

Throttle Ø 1,2 mm [0.047 inch]

X15

Throttle Ø 1,5 mm [0.059 inch]

X20

Throttle Ø 2,0 mm [0.079 inch]

X30

Throttle Ø 3,0 mm [0.120 inch]

X40

Throttle Ø 4,0 mm [0.160 inch]

Clamping length

42 mm [1.65 inch] (Standard)

Z

22 mm [0.87 inch]

Control spool play

Standard (recommended)

T06

Minimum

T12

Increased

Seal material

NBR seals

V

FKM seals

MH

Recommended for operation with HFC hydraulic fluids together with high temperatures

MT

Low-temperature version

Approval

Standard

=UR

Solenoid coil as approved component with UR marking according to UL 906, edition 1982

=CSA

Approval according to CSA C22.2 No. 139-1982

=AN

Porting pattern according to ANSI B93.9

Locating hole

Without locating hole

/62

With locating hole and locking pin ISO 8752-3x8-St

Electric power consumption

Standard

SO407

With reduced electric power consumption

Additional details

-86

-86

-87

-87

/60

/60

/60SO407

/60SO407

/Z=ANSO43A-1799A

/Z

+BOLTSM5X50

+BOLTSM5X50

+G342

+G342

+PLUGINCONNECTOR

+PLUGINCONNECTOR

=AN

AN

=CSA

CSA

=KM

KM

=PL

PL

=SH

SH

03

03

03/B08

03/B08

03/MT

03/MT

6

6

6/V

6/V

6/VSO9

6/VSO9

6/ZV

6/ZV

60

60

62

62

62=AN

62

62=CSA

62

62=UR

62

62SO21

62SO21

62SO407

62SO407

62SO407=AN

62SO407

62SO43A-1018

62SO43A-1018

62SO43A-1042

62SO43A-1042

62SO43A-1096

62SO43A-1096

62SO43A-1338

62SO43A-1338

62SO43A-1461

62SO43A-1461

62SO43A-1654

62SO43A-1654

62SO43A-1723

62SO43A-1723

62SO43A-1773

62SO43A-1773

62SO43A-1777

62SO43A-1777

62SO43A-1797

62SO43A-1797

62SO43A-1799

62SO43A-1799

62SO43A-1799A

62SO43A-1799A

62SO43A-1809

62SO43A-1809

62SO43A-1855

62SO43A-1855

62SO43A-686-1

62SO43A-686-1

62SO859

62SO859

62SO888

62SO888

62SO9

62SO9

62SO99

62SO99

B00

B00

B05

B05

B05SO526

B05SO526

B07

B07

B14=CSA

B14

B14=CSA=AN

B14

B16

B16

B16=AN

B16

B16=CSA

B16

B16=CSA=AN

B16

B16SO43A-1799A

B16SO43A-1799A

B18

B18

B18=UR

B18

B18MH

B18MH

B18SO407

B18SO407

B18SO43A-1799+1833CAT

B18SO43A-1799+1833CAT

B18SO899

B18SO899

B18V

B18V

B22

B22

B24SO43A-1799+1833CAT

B24SO43A-1799+1833CAT

B28

B28

B28V

B28V

B35

B35

H00

H00

H00SO407

H00SO407

H05

H05

H18

H18

H22

H22

JLG

JLG

L

L

L/V

L/V

LQMBG24

LQMBG24

LV

LV

ML

ML

N05

N05

N14

N14

N18

N18

N28

N28

N28V

N28V

QLAG24/B12

QLAG24/B12

QRAG24S

QRAG24S

QRBG24S/ZV

QRBG24S/ZV

QYAG24

QYAG24

QYBG24

QYBG24

R00/62

R00/62

R04

R04

R04SO407

R04SO407

R22

R22

R22V

R22V

R35

R35

S043A-1799

S043A-1799

SO194

SO194

SO21

SO21

SO256

SO256

SO258

SO258

SO292

SO292

SO293

SO293

SO343

SO343

SO43A-1042

SO43A-1042

SO43A-1096

SO43A-1096

SO43A-1221-A

SO43A-1221-A

SO43A-1338

SO43A-1338

SO43A-1338JLG

SO43A-1338JLG

SO43A-1743

SO43A-1743

SO43A-1777

SO43A-1777

SO43A-1799

SO43A-1799

SO43A-1799+1833

SO43A-1799+1833

SO43A-1799+1833CAT

SO43A-1799+1833CAT

SO43A-1799A

SO43A-1799A

SO43A-1809

SO43A-1809

SO43A-1820A

SO43A-1820A

SO43A-1820B+1338

SO43A-1820B+1338

SO43A-1820C+1338

SO43A-1820C+1338

SO43A-1822

SO43A-1822

SO43A-1833

SO43A-1833

SO43A-1852

SO43A-1852

SO43A-1860

SO43A-1860

SO43A-1870

SO43A-1870

SO43A-1871

SO43A-1871

SO43A-1872

SO43A-1872

SO43A-1872-A

SO43A-1872-A

SO43A-1872-A=AN

SO43A-1872-A

SO43A-1872=AN

SO43A-1872

SO43A-686-1

SO43A-686-1

SO43A-978-1

SO43A-978-1

SO43A1799-1839

SO43A1799-1839

SO43A686-1

SO43A686-1

SO461

SO461

SO523

SO523

SO524

SO524

SO525

SO525

SO529

SO529

SO530

SO530

SO531

SO531

SO533

SO533

SO534

SO534

SO561

SO561

SO617

SO617

SO680

SO680

SO692

SO692

SO694

SO694

SO722

SO722

SO778

SO778

SO797

SO797

SO806

SO806

SO810

SO810

SO811

SO811

SO828

SO828

SO829

SO829

SO851

SO851

SO855

SO855

SO859

SO859

SO859SO43A-1741

SO859SO43A-1741

SO871

SO871

SO880

SO880

SO887

SO887

SO888

SO888

SO889

SO889

SO895

SO895

SO896

SO896

SO898

SO898

SO9

SO9

SO9=AN

SO9

SO9=CSA

SO9

SO9=UR

SO9

SO907

SO907

SO931

SO931

SO941

SO941

SO942

SO942

SO951

SO951

SO956

SO956

SO99

SO99

SO99=CSA

SO99

SO9JLG

SO9JLG

X04/62

X04/62

X18

X18

X27/62

X27/62

X28V

X28V

ZV

ZV

说明文档

Add to basket

| You have successfully finished your selection. |

| 物料代码: |

Product description

产品型号:WE66X/E

| The following data were selected. | ||

|---|---|---|

| Type | WE | Directional valve |

| Size | 6 | Size 6 |

| Series | 6X | Series 60 … 69 |

| Solenoid version | E | High-power solenoid, wet-pin, with detachable coil |