automatica

As the world’s leading trade fair for smart automation and robotics, automatica brings together all key technologies in the international technology hub of Munich. This makes it a meeting point for constructive and visionary cross-sectoral exchange between industrial, research and political representatives. And there is more: It offers an overview of global developments, topics, innovations, and solutions, thus providing the necessary orientation and investment security in these times of upheaval. So that the vision of gradual advancement from automated to autonomous production may become reality – providing a growth opportunity for you and your company.

Get the most out of digitalization and sustainability?

Whatever may be your motion challenge, at Bosch Rexroth we have the right technology and the right people to support you and your project.

At automatica 2023, be impressed by how the modular solutions from Bosch Rexroth enable you to benefit from digitalization in your everyday operations.

Discover how you can improve the sustainability of your plants with us and make your contribution to climate protection. Our technology makes it possible – how would you like to benefit from it?

Visit us at our booth in hall A6 booth 502!

Video YOU DECIDE.

automatica 2023

Site map

Tickets

Your contact to Bosch Rexroth

Linear Motion Technology – automate sustainable

Do you want to implement linear movements in your applications quickly, efficiently and in a future-oriented manner? Our consistent product range offers you the right solutions for industrial automation: from linear guides, linear axes and screw drives to electromechanical cylinders and integrated measuring systems. Smart mechatronic solutions such as linear robots complete the portfolio.

Smart compensation element for robots

Discover new possibilities for your automation. The Smart Flex Effector, our sensor-based compensation unit with independent kinematics in six degrees of freedom, gives robots the feel of a human hand and increases precision. Processes that are difficult to control or can only be carried out manually up to now can be automated, optimized and monitored by simply retrofitting the Smart Flex Effector.

Smart Item Picking

Our toolkit is a software solution that enables industrial robots to autonomously handle objects. It automates picking tasks and processes in logistics, recognizing a large number of objects without teaching in thanks to AI. The solution can be adapted to customer requirements and is easy in operation. High pick rates increase productivity, compensate for capacity bottlenecks, and reduce error rates.

Battery Recycling

Raw materials account for a large part of the manufacturing costs of lithium-ion cells. Bosch Rexroth solutions reduce raw material consumption and costs. At the end of the product life cycle, battery packs are dismantled down to their individual parts. We support the return of valuable raw materials to the manufacturing process - with scalable and economical system solutions. Absolutely sustainable.

ACTIVE Shuttle

The AMR ACTIVE Shuttle is making entry into the factory of the future: it is implemented quickly without adapting the existing factory infrastructure, intuitive to operate, completely connected and safe for people to use! ACTIVE Shuttle automates and standardizes your material supply. In the future, transport your dollies that are loaded with Small Load Carriers in a highly flexible and secure manner.

OPEX

With the OPEX digital torque wrench, Rexroth has added a particularly economical new product to its existing range of tightening solutions. With OPEX, both the torque and the angle of rotation can be measured and tightening results are transferred to any IT system. The OPEX tool sets new standards when it comes to accuracy and allow fatigue-free work thanks to their ergonomic design.

ctrlX AUTOMATION for robotics

The implementation of robots often ties up significant engineering capacities. The automation toolkit ctrlX AUTOMATION makes it easy for you to put in place individual robotic solutions and achieve quick and efficient engineering. This enables you to put robots into operation more quickly and shortens the time-to-market.

Level up your mobile robots

Automate your mobile robots according to your needs with our modular, flexible, open and efficient automation kit. This means less development effort, cabling, interfaces and components for you. The software and hardware components of ROKIT – The Robotics Kit and the automation toolbox ctrlX AUTOMATION can be integrated into your vehicles step by step.

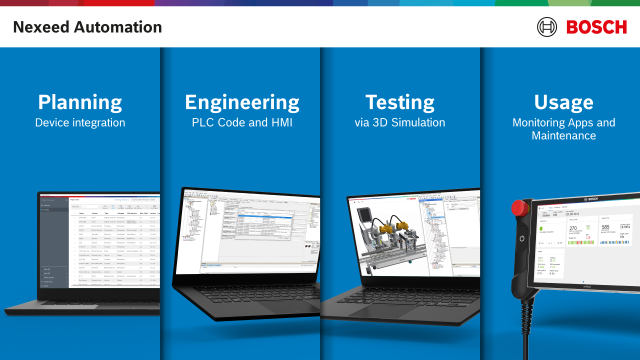

Nexeed Control plus

Nexeed Control plus reduces machine development time by up to 50 % through seamless engineering over the phases: planning, engineering, testing and usage.

- Easy device integration thanks to modular blocks

- Automatic generation of HMI visualizations

- Reuse through modular blocks

- Virtual commissioning and hardware testing with the integrated 3D model sequence simulation