Industries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Consumer goods

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

Service

OverviewCompany

OverviewProduct groups

OvervieweConfigurators and Tools

OverviewTrainings

Overview- Home

- Products

- Product groups

- Assembly Technology

- Identification Systems RFID

Reliable and secure flow of information

SECURE AND RELIABLE DATA COMMUNICATION

with Rexroth RFID solutions

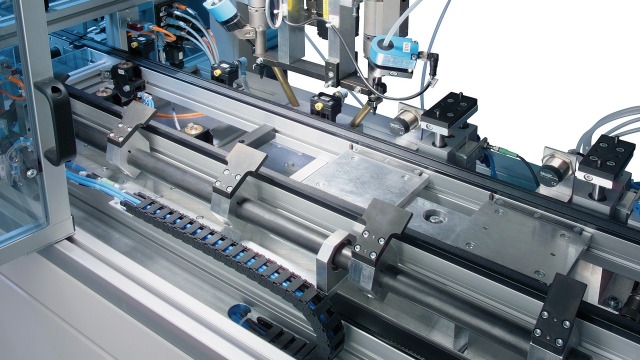

RFID systems ensure the flow of information accompanying goods in the assembly lines. Object-related data enable the targeted control of process and processing steps, as well as the type- or variant-dependent inward and outward transfer of workpiece pallets during the production of product variants on branched, flexible assembly systems. By documenting all process steps and production data, traceability when errors occur is also possible.

All RFID systems from Rexroth are read/write systems and support common field buses. They are perfectly matched to the Rexroth conveyor systems.

Product overview RFID systems

RFID system ID 200

With ID 200, RFID solutions can store data both centrally and decentrally. The use of standardized frequencies and transmission protocols allows the use of commercially available data tags.

With ID 200, RFID solutions can store data both centrally and decentrally. The use of standardized frequencies and transmission protocols allows the use of commercially available data tags. It is also modular and simple to install.

Key features

- Interfaces: PROFIBUS DP, Modbus/TCP, EtherNet/IP, ProfiNet, TCP/IP, RS232

- Max. memory capacity: 2 KB

- Max. reading distance: 35 mm

RFID system ID 15

The Rexroth identification system ID 15 enables targeted workpiece pallet control to the corresponding workstations.

With its compact size, ID 15 is perfect for small systems and central data storage. In contrast to comparable systems, ID 15 can also identify passing workpiece or data tags – completely reliably and running up to a speed of 20m/min.

Key features

- Interfaces: AS-i-Bus

- Max. memory capacity: 15 Bit

- Max. reading distance: 20 mm