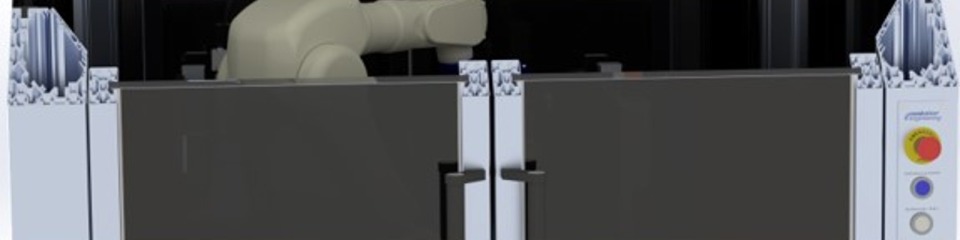

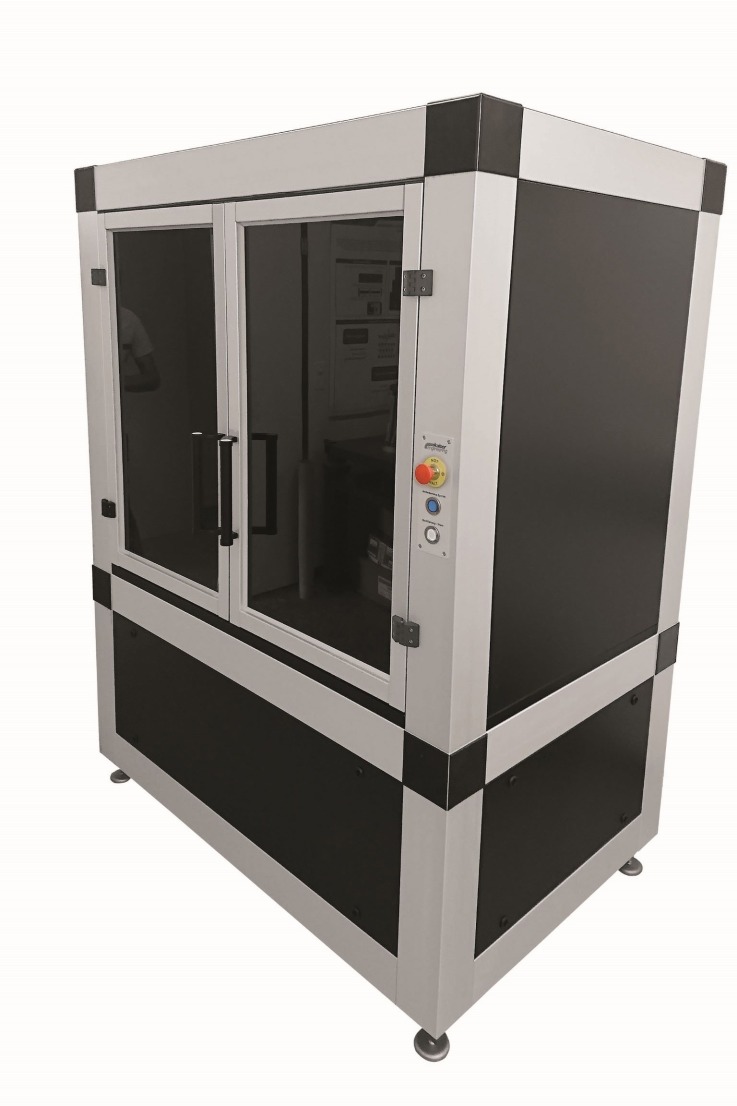

Maximum design freedom: Kaiser engineering achieved this goal with the help of Bosch Rexroth. The task: the cost-efficient construction of a robot cell for measuring coffee capsules. The way: function-integrated profiles from the aluminium profile construction kit.

Kaiser engineering GmbH has been successfully involved in special machine construction for over 50 years. But every enclosure has individual requirements, as in the case of a robot cell for measuring coffee capsules. In order to streamline the design, Kaiser engineering GmbH used the function-integrated profiles (FIP) from the aluminium profile construction kit of Bosch Rexroth AG for the first tim

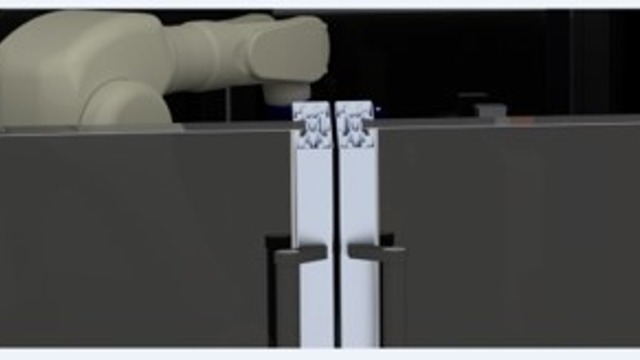

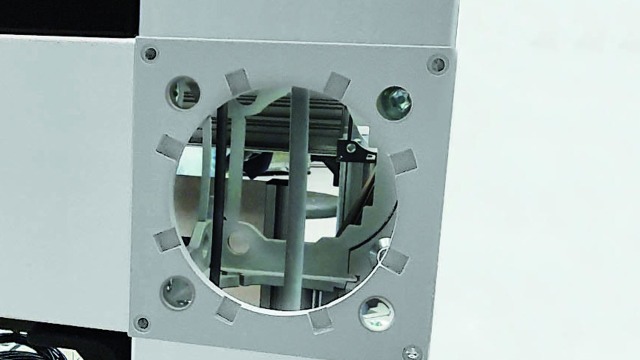

Profile node with internal cable guide

The basic idea of the function-integrated profiles are stable construction profiles that have an integrated cable duct. This automatically creates internal cavities for the subsequent cabling during the construction of the frame.

The appearance remains unchanged and a clean machine design is created. Even at the profile joints, the cables are invisible, as they are simply routed through the patented profile nodes. Cable ducts mounted from the outside are history.

"The function-integrated profiles from Bosch Rexroth allow us a high-quality, clean and uncluttered frame design in special machine construction that is characterised by a high recognition value."

Michael Karth, Project Manager Marketing at Kaiser engineering GmbH

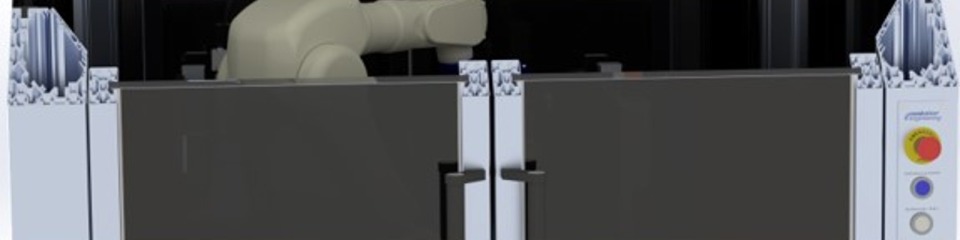

Kaiser engineering proves the scalability of the design with further constructions based on FIP. These are characterised by an identical structure in the company's own design, which increases the recognition value.

This not only positions Kaiser engineering as a high-performance special-purpose machine manufacturer for its customers. Rather, standardisation also leads to increased design efficiency. Bosch Rexroth Certified Excellence Partner FMS-Technik AG in Switzerland ensures the necessary availability of the material.

Vibration-resistant machine housing for robot arm

Produktmanager Shopfloor Solutions at Bosch Rexroth AG.

Are you ready for our modular system for safe aluminium profiles?