Machine manufacturer ILLIG brings a good dose of flexibility and future-proofing to the changing food packaging industry and relies on the technological openness of the ctrlX AUTOMATION modular automation system from Bosch Rexroth to achieve this.

Packaging is an important lever for climate protection. Political regulations such as the European Plastic Act aim to limit the use of plastics. The food industry pursues this goal, among other things, with cardboard-plastic combinations and laminated trays made of cardboard or pulp whose components can be separated for recycling.

From the point of view of the machine manufacturers, however, it is uneconomical to realise and maintain a separate series for each type of packaging. Much more economical are modular system concepts such as the XLU series, which the internationally active ILLIG Maschinenbau GmbH & Co. KG has realised with the help of the future-oriented ctrlX AUTOMATION modular automation system from Bosch Rexroth.

The Heilbronn-based company is one of the world's leading suppliers of thermoforming and packaging systems as well as tooling systems for cardboard, paper and plastic. With the XLU product family presented at Interpack 2023, the tradition-steeped family business has created a future-oriented machine series that significantly expands the application possibilities for laminating pulp and laminating cardboard. For the greatest possible freedom in the choice or combination of packaging material, the modular XLU series is available in three versions: While the CLU type erects and laminates cardboard trays, the PLU designation stands for the lamination of containers made of pulp. The TLU version, on the other hand, provides plastic trays with a cardboard cover (tray labelling).

Fast and efficient thanks to the modular solution approach (Image source: ILLIG Maschinenbau GmbH & Co. KG)

In addition to flexibility, a key customer requirement was the future-proofing of the series. "Packaging machines are long-term investments that have to function for twenty years and more," explains Markus Peter, Head of Electrical Development at ILLIG Maschinenbau. To ensure that the new machine concepts can follow the advancing digitalisation as required, ILLIG opted for the open automation solution ctrlX AUTOMATION from its long-standing technology partner Bosch Rexroth. "Our machines must be open on the software and hardware side for future applications and modifications," emphasises Markus Peter. "Bosch Rexroth offered us optimal conditions for this."

With ctrlX AUTOMATION, ILLIG has opted for a new generation of control and drive technology that is characterised by the greatest possible flexibility and openness to match the machine concept. "The modular solution approach forms a good platform for the development of future-proof machines," explains Markus Peter. "The open hardware and software modules ensure high process quality and enable data to be obtained for continuous improvement and increased efficiency in terms of productivity and energy efficiency."

"The modular solution approach forms a good platform for the development of future-proof machines"

Markus Peter, Head of Electrical Development at ILLIG Maschinenbau GmbH & Co. KG

For the automation of the modular machine series, ILLIG uses, in addition to the ctrlX CORE control platform, I/O modules, ctrlX I/O and the compact ctrlX DRIVE servo drives with precise MS2N servo motors for all process-relevant axes such as handling, film unwinding or product feeding via a turntable. Thanks to the combination of scalable drive technology and highly integrated dual-axis devices, inverters, inverters and I/Os, the control cabinet is significantly smaller. In the case of the XLU series, the space saving amounts to about 40 percent compared to the conventional design.

ctrlX AUTOMATION also offers machine builders a great deal of design freedom when it comes to internal and external networking. ILLIG chose the industry standard EtherCAT for bus communication at machine level, which allows customer-specific components from different manufacturers to be seamlessly integrated. "Bosch Rexroth had been set as an automation partner for a long time," reports Markus Peter. In addition to the technological openness, the industry expertise and excellent application support also spoke in favour of expanding the cooperation. "Bosch Rexroth supported us intensively and at eye level during the basic engineering of the new machine series," says the Head of Electrical Development. "The support in project planning and design of drives, I/Os and other modules, helped us a lot to keep to the tight schedule."

Premiere at Interpack 2023: The modularly designed Illig XLU machine series brings efficiency and future-proofing to food packaging with Bosch Rexroth's ctrlX AUTOMATION modular automation system. Here the PLU type for laminating pulp trays (Image source: ILLIG Maschinenbau GmbH & Co. KG)

With the new, scalable automation modular system, ILLIG is able to implement both small and complex applications economically. Flexible programming is a key factor here. "We can use the most suitable language depending on requirements, including current IT languages such as Java, JSON or Python," clarifies Markus Peter. "In times of a shortage of skilled workers, this makes it easier to find programmers. Our specialists quickly found their way in the new automation world and were able to adopt many existing codes. With ctrlX AUTOMATION, we can continue to support technology that is more than twenty years old without any problems. This brings sustainability to automation."

Bosch Rexroth's decades of experience in motion applications, among other things, flowed into the development of ctrlX AUTOMATION. This is also reflected in web-based development environments that meet the low-code requirement. The ctrlX CORE control can also be simulated virtually on a PC, which speeds up the programming of the system. "The code created with virtual axes was quickly ready and could be put into operation in advance," says Markus Peter. "We only had to convert the built machine to the real axes, which saved further time."

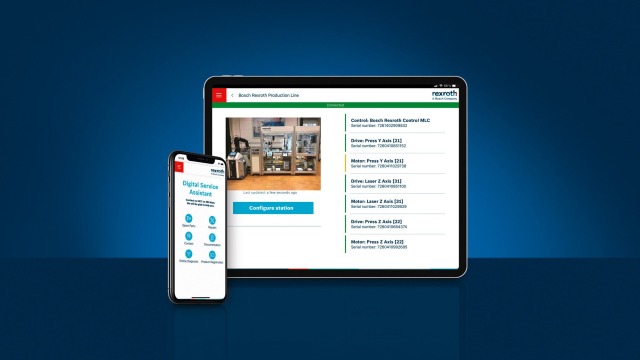

In addition to the various disciplines such as control, programming, security and apps, the holistic approach of ctrlX AUTOMATION also includes a forward-looking service concept with software updates, 24/7 support hotline and worldwide spare parts supply with long-term availability. International suppliers such as ILLIG can thus secure their customers' investments for 25 years and more. Digital tools such as the ctrlXDigital Service Assistant, the Service Indicator and the ctrlX Device Portal enable fast remote diagnostics, troubleshooting and the roll-out of new apps and software features.

"For their needs-based development work, Rexroth customers will find a wide range of apps from Rexroth and third-party providers from the partner world ctrlX World for a variety of industrial automation tasks in the ctrlX Store," explains Tobias Gerhard, responsible for Business Development in the Consumer Goods division at Bosch Rexroth. "In addition, we provide applications and libraries for individual app creation, which further increase the degrees of freedom."

Digital Service Assistant - fast help in case of service (Image source: Bosch Rexroth AG)

The end product: cardboard and pulp trays (Image source: Maschinenbau ILLIG GmbH & Co. KG)

From the company's point of view, the decision in favour of ctrlX AUTOMATION and the associated reduction of the total cost of ownership contributes to sustainably strengthening its position in international competition, also finds Chief Technical Officer (CTO) Jürgen Lochner. "With this unique combination of technological openness and procurement security, we have succeeded in creating an optimal cost structure for our customers in fast-moving times. This allows us to expand our international competitive position with modular machine concepts while offering attractive retrofits."

Editor's note: Following the takeover by a German SME investor, the company has continued to operate under the new name ILLIG packaging solutions GmbH since August 1, 2024.

Learn more about how ctrlX AUTOMATION meets the demands of the production world.

Author: Tobias Gerhard

Position: Senior Business Development Manager Consumer Goods in Central Europe Sales, Bosch Rexroth AG