How can you make mixing mills for rubber even safer and more energy-efficient? Comparative analysis in practice at Freudenberg Sealing Technologies shows how a speed-controlled direct drive from Bosch Rexroth with Hägglunds’ hydraulic motors is setting new standards in the rubber industry.

Occupational safety has always been a key requirement for roll mills and calenders in the rubber industry. In addition to the total cost including operation and maintenance, energy efficiency is also a crucial factor when it comes to deciding on a purchase. Which drive technology performs better in all aspects in an actual application? Electromechanical or hydraulic? Freudenberg Sealing Technologies wanted to know the answer to this very question and had two drives compete against each other.

Freudenberg Sealing Technologies is part of the Freudenberg Group, a well-established technology company and global market leader in sophisticated, innovative solutions for sealing applications and e-mobility systems. In the 2023 business year, the company generated sales of around €2.55 billion and had more than 13,000 employees.

Freudenberg Sealing Technologies produces axle boots and other rubber parts at its Berlin location. “High-performance drives with high torque are required to mix the raw materials for natural and synthetic rubber and process them further,” explains Marek Semrau, Senior Global Process Engineer at Freudenberg Sealing Technologies. “The materials, some of which are highly viscous, are first mixed in what is known as an internal mixer before they fall into the roll mill as rubber bales. There, they are mixed again by repeated retraction, slowly cooled, and finally drawn off as different blanks for subsequent vulcanization.”

According to Semrau, the performance characteristics of roll mills and calenders are clearly a strong argument for hydrostatic direct drives. “However, due to the increased demands for energy efficiency, electromechanical drives have also been purchased in recent years,” says Semrau. “But the mechanical transmission systems, which weigh around six metric tons per roller, have specific disadvantages, such as high inertia and large size, which we do not have in the case of hydraulic drives.”

In 2016, Bosch Rexroth and Freudenberg Sealing Technologies started a collaboration project to find out whether a modern hydraulic drive can compete with a five-year old electromechanical drive in terms of energy efficiency. Semrau commissioned the well-established system integrator MaTech – Maschinen und Technik GmbH – with the comparative analysis for the conversion in Berlin to a new compact drive designed by Bosch Rexroth.

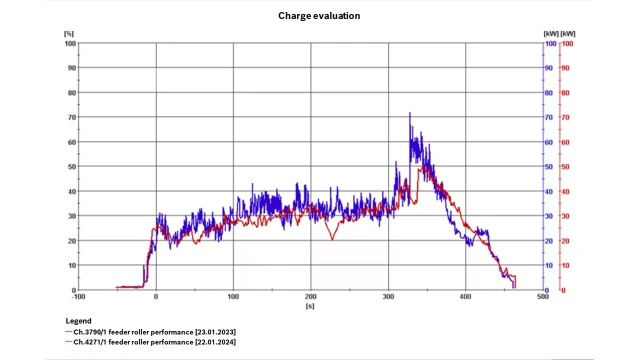

Lower power consumption: The red curve of the hydraulic solution from Bosch Rexroth shows a lower power requirement with fewer load peaks than the electromechanical version (purple). (Image source: Freudenberg Sealing Technologies)

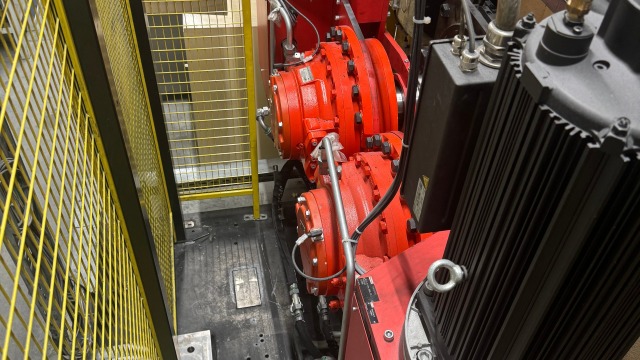

Compact and energy efficient after modernization: The Hägglunds hydraulic motors connected to the rollers are run directly via speed-controlled axial piston pumps in a closed circuit. (Image source: Freudenberg Sealing Technologies)

The new, speed-controlled compact drive with a continuously variable hydrostatic transmission system for the rubber industry is available in six output classes from 15 to 120 kW. Depending on the application, a robust Hägglunds radial piston motor from the Compact CA or Quantum QMX series is used. The hydraulic motor is operated in a closed loop fluid circuit by a variable-speed drive comprising a water-cooled servo motor and axial piston pump.

“Such hydrostatic transmissions systems with a variable gear ratio are powerful, quick to control, and low maintenance,” says Jörg Schlegel, Managing Director of Maschinen und Technik GmbH. “At the same time, however, we will also achieve greater energy efficiency.” The two roller drives for the conversion project at Freudenberg Sealing Technologies each power 55 kW and use a Hägglunds CA100 hydraulic motor with a rated torque of 25,000 Nm (max. 33,500 Nm) and a nominal speed of up to 23 min-1.

As comparative measurements at Freudenberg show, the new direct drive solution for roll mills and calenders achieves significantly shorter braking angles than the electromechanical drive. For a company that focuses on safety like Freudenberg Sealing Technologies, this is an important criterion. As according to the recommendation by the Deutsche Gesetzliche Unfallversorgung (DGUV – German Social Accident Insurance), the rollers may only rotate another 45° at the most after making contact with the emergency stop bar, which corresponds approximately to the length of one hand.

While mechanical transmission systems can at best reproduce approximately 20° braking angles without any risk of damage, the Rexroth solution impresses with a value of 3.5°. As a result, retraction into the rollers rotating in opposite directions is technically impossible. This was achieved using a redundant quick-stop through the electrical resistance in the frequency converter and a mechanical brake in the servo motor. “This is a huge benefit for safety and sets a new benchmark in the industry,” says Semrau, whose project ranked first in the company’s internal innovation award.

Bosch Rexroth’s speed-controlled direct drive, mounted on the mixing roll mill, uses water-cooled servo motors (front and rear) to each drive an axial piston pump. The two Hägglunds CA100 radial piston units can be regulated precisely and quickly by both actuators – motor speed and adjustment angle. (Image source: Freudenberg Sealing Technologies)

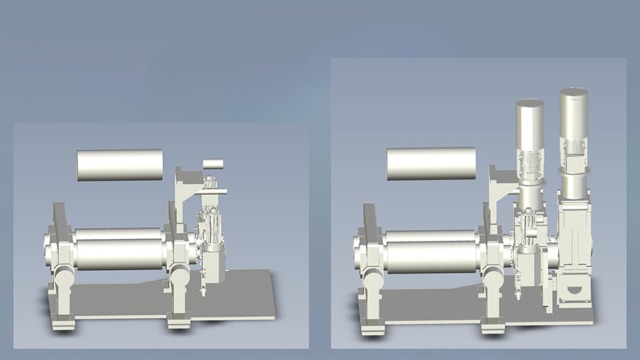

More compact and lighter: The mixing roller with hydraulic motor (left) is much more streamlined than the electromechanical version with transmission system (right). (Image source: Freudenberg Sealing Technologies)

In terms of energy savings, the comparative measurements have shown that the innovative solution with a hydraulic motor performs at least equally well as, and in some cases, even better than the electromechanical drive, depending on the process. Compared to a conventional hydraulic supply, the energy savings are about 40 %. The fact that there is still room for even more gains is demonstrated by further measurements on the machine in Berlin, which were evaluated as part of the joint collaboration project. Accordingly, oil viscosity and the associated oil temperature have a major influence on energy consumption, which is why Freudenberg wants to evaluate other fluids.

Another advantage: The new Hägglunds drive solution from Bosch Rexroth reduces the drive footprint by around 40 % compared to the electromechanical version, while the total weight per drive has dropped from over 6,000 to about 780 kg. The amount of fluid required is also significantly less. While it was approximately 300 l for both bevel spur gears, the hydraulic drive makes do with a fluid quantity of 60 l, including the small feed unit for secondary functions.

Semrau also identifies improvements in performance: “Without mechanical transmission, the full torque is immediately available when required, and in fact without a time limit.” By contrast, the electromechanical solution’s motors designed with the same power had to be overloaded more frequently due to the process as a result of the transmission system’s inertia. For example, the strong acceleration to remove the rubber strip caused a peak power of 85 instead of 55 KW. If the same process step is carried out with the new drives, no load peaks can be detected for the electric motor in the process, which could theoretically result in another reduction of the installed power. Another feature of the hydrostatic drive is the infinitely variable friction, i.e. the speed ratio between the rolls, which permits more stable process control on the roll mill.

When looking at the total costs, there is also a strong argument for hydrostatics, which according to Schlegel from MaTech is virtually maintenance-free. “We expect a service life of 20 to 30 years. Mechanical transmission systems have to be replaced at least once during this time. In addition, the hydrostatic solution’s hydraulic fluid usually needs to be changed less frequently. In order to ensure the highest possible availability, Freudenberg Sealing Technologies uses the drive control to monitor important parameters such as oil temperature and filter condition. In another application Freudenberg uses the Hägglunds CMp data-based analysis service for predictive maintenance.

Semrau rates the comparative analysis as a clear success: “In my view, there is currently no better drive for roll mills and calenders. I can imagine that the new drive concept is also interesting for other applications outside the rubber industry.” In light of the good results and reliable operation, Freudenberg Sealing Technologies is expanding the project and procuring three new roll mills, as well as equipping two more roll mills with the new compact drive system.

The potential for retrofits is also obvious to Schlegel. “Given the long service life of roll mills and calenders and energy savings of around 40 % compared to an older hydraulic drive, I expect great demand. Bosch Rexroth is an ideal partner for this, providing everything from function descriptions to software modules for flexible connection to higher-level control systems," says Semrau.

Bosch Rexroth’s new speed-controlled compact drive for the rubber industry gets more performance out of less power and hydraulic fluid. The speed-controlled servomotor in combination with an infinitely variable hydrostatic transmission ensures that torque is provided as required and that the drive works efficiently at every load point. Compared to conventional hydraulic power units, energy savings of around 40 % are possible.

Author:

Daniel Becker

Position:

Sales Hägglunds Europe Central Bosch Rexroth AG, Product Group Large Hydraulic Drives