In the wood-processing industry,the focus is on the best possible use of raw materials, high productivity and efficiency. Aquitaine Electrique designs, implements and modernizes sawing lines with the aim of continuously improving these aspects.

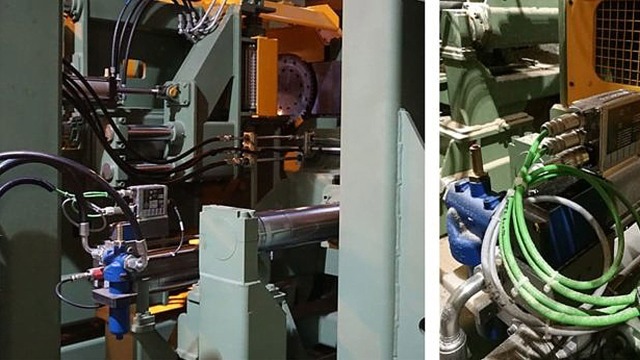

Bosch Rexroth’s servo valves can be used at all stages of the wood cutting and are currently installed on a large number of machines including stops, canters, slabbers, edgers and more. The servo valves are used both for new lines as well as in lines that are under modernization.

One of the benefits of the our connected valves is that they contain integrated digital axis control (IAC-Multi-Ethernet) which actively controls the axes independently of the machine control by using separate motion functionality and processes the data of various sensors that can be connected directly.

Each valve is locally connected to the general power supply and communication network. Only a few dozen centimetres of cable are needed where previously each valve would have had to be wired to the cabinet. When you consider that a saw line often contains dozens of axes, it’s clear how this simplification of wiring can greatly reduce setup times. By reducing the cable lengths and the cabling effort, we also reduce the challenges of connection faults, loss of signal or damaged cables, greatly increasing the reliability of the line.

A multi-ethernet interface and a unique IP address for each servo valve allows Aquitaine Electrique to easily identify them and provide remote troubleshooting via a VPN module. The state of each valve can be identified, and issues addressed in a targeted manner.

“After 3 years of use, we have chosen to extend the integration of the valves connected to all of our lines and to permanently abandon the use of valves that do not contain an integrated axis controller. These new valves have allowed us to make a lot of progress on start-up times as well as on after-sales service.”

– Patrick Dziura, Director of Aquitaine Electrique

Connectivity is essential in order to develop a flexible production model, with frequent demand changes. Customers only require a single spare valve, if needed they can use that valve on any axis, and it can be programmed remotely by Aquitaine Electrique in just a few minutes.

To find out more about connected valves click here.