With the opening of our second building, our Customer and Innovation Centre in Ulm brings together all of our expertise in factory automation, industrial hydraulics and mobile machinery in one location. With the name CU.BE, which stands for CUstomer BEnefits, the new building reflects our ambition to create a customer-focused experience, customer-oriented solutions and a space where you can experience current and future innovations first-hand.

The CU.BE not only serves as a central contact point for customers, users, partners and our employees, but is also a central place where we can collaborate, exchange ideas and plan new projects - with customer benefit always at the heart of everything we do. The Bosch Rexroth Academy is also on site and conducts training and education for customers and users in all technologies and areas of expertise.

The Customer and Innovation Centre, spread over two buildings, comprises the CU.BE and the Innovation Lab, which house laboratories, offices, seminar and training rooms and an exhibition space. On the outside there is the TechPark, a 10,000sqm area with workshops and a test and demonstration area for electrically powered mobile machines. There is space there, for example, for demonstrating earthmoving work such as agricultural technology.

The complex was built in an environmentally friendly way and according to the latest standards. The CU.BE has a low CO₂ energy supply, a photovoltaic system on the green roof for optimal use of solar energy and wall panels made of renewable building materials. Thanks to its open architecture, the building control system is ready for further measures to increase energy efficiency and conserve resources during operation.

The CU.BE offers you an experience under the motto "One Bosch Rexroth" with numerous exhibits, components and system solutions that provide an up-to-date overview of all our technologies in one place. Demonstration models and prototypes show innovations and groundbreaking developments at an early stage, providing you with valuable insights into upcoming trends.

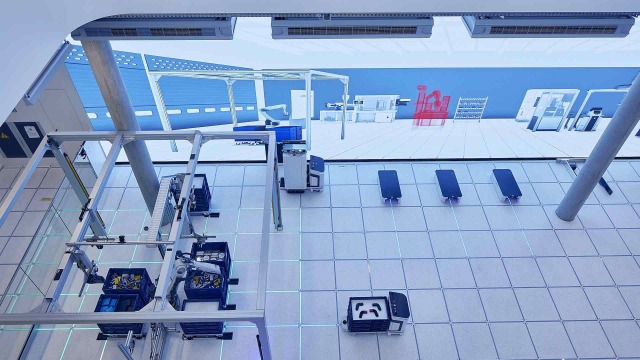

Our vision of the factory of the future is brought to life in the model factory, which is also housed in CU.BE. Using concrete use cases and a real production scenario, including intralogistics, we present our powerful yet practical portfolio to give you a real impression of what the manufacturing of the future will look like.

For mobile machines, the TechPark offers a high-performance test bench for electrification, workshops for retrofitting, a training centre and a test track with an area where typical work can be carried out.

Customers can visit the centre either by appointment or at one of our events, such as our Tech Days, hackathons and trade fairs. If you can't visit the centre in person, there are also digital options.

With the opening of the CU.BE, the centre will become one of the main locations of the Bosch Rexroth Academy and offer a state-of-the-art venue for the training and further education of technical specialists and managers. The training on offer includes courses on specific technologies as well as offerings on overarching topics such as energy efficiency, the Internet of Things, Industry 4.0 and machine safety. The training rooms are equipped with all relevant systems, and courses can be held on-site, in a hybrid format or completely digitally.

The Innovation Lab serves as a place where we pool our expertise in software solutions and digitalisation of all our technologies. Developers from different business units share their knowledge in agile teams and work simultaneously with customers, business partners, start-ups and experts from academia. By working closely together from the very beginning, we are able to quickly develop holistic, innovative and customer-oriented solutions.

Disruptive developments start with Minimum Viable Products (MVP), on which users can give immediate feedback so that this can be incorporated into the functionalities. Using prototypes and demonstration models, developers and customers can then test the actual functions in current products at an early stage. This enables us to quickly come up with innovative new solutions that are geared to the needs of our customers.

For several years, we have been driving cultural change in our company - towards more diversity, greater willingness to change, customer-centricity and agile approaches. Our CU.BE will not only be a centre for innovation, but also an "incubator" for our future-oriented work culture. One of the goals of the centre is to build international networks of employees from different areas and to promote project-oriented work - in other words, there are more workplaces than necessary so that employees can choose their workspace on a daily basis according to the requirements of their team.

The centre is not only built in an environmentally friendly way, but also has other important climate-related benefits. One of the most important areas we will focus on in the Innovation Lab is the development of solutions that help customers and users improve their energy efficiency and conserve resources.

One example of this is mobile machinery. The new facilities enable us to work with our customers on new electrification solutions for off-road vehicles, such as construction and agricultural machinery. Another example is factory automation, which is demonstrated in our model factory. As the factory of the future will be very flexible, fewer factories will be needed, which will clearly have a positive impact on the environment. The reuse of components and solutions also contributes to the efficient use of resources.

Digitalisation is a theme that runs through all our technologies and is an important focus for our developers in the Innovation Lab. We are driving the electrification and digitalisation of hydraulic solutions to further increase the energy efficiency and productivity of fluid technology.

In the meantime, our model factory is fully digitised and has digital twins, not only for the individual solutions, but also for the production lines. The Internet of Things is also playing an increasingly important role in mobile machines, be it in the updating of subsystems or in remote diagnostics. At our new centre in Ulm, we are able to incorporate new technologies into real vehicles and optimise them together with OEMs.

The more complex and versatile technology becomes, the more important it is to keep things simple. In the model factory, we make the Plug & Produce promise a feasible reality. Components, modules, subsystems and system solutions identify themselves, recognise their tasks and are ready for use at the touch of a finger. In fact, the model factory can already be operated with a tablet PC.

Robots are playing an increasingly important role in factory automation, supporting and collaborating with humans. In the robotics laboratory of the Customer and Innovation Centre, we work together with our customers on the next generation of robots. The goal is to develop programming-free robots for various tasks while ensuring safe operation in all situations. The developers' task is also to innovatively link robotics and image processing systems.

Artificial intelligence (AI) and data analytics are key technologies of the future. That's why we have set up a separate area for them in the Innovation Lab. Our experts focus on real applications, for example the use of artificial intelligence in welding technology for in-situ monitoring of welding processes and adaptive control in conjunction with cloud connectivity. This enables users in the automotive industry to achieve measurable improvements in quality assurance and productivity.

Services such as maintenance and repair have an enormous impact on the performance and cost efficiency of machines. In Ulm, our service experts are therefore exploring the growing potential of digital services - the customer contact points of the future. This includes integrating new services into existing structures or setting up remote access to production areas to guide employees through monitoring and maintenance processes.

As with everything worked on at CU.BE, the focus is on exploring technologies, leveraging our cross-functional expertise and finding the best approaches to create innovative solutions with real CUstomer BEnefits.