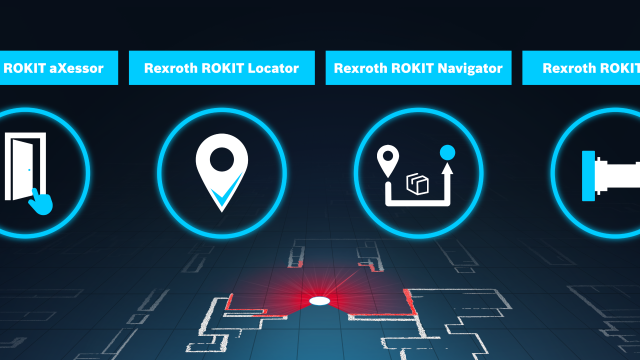

Rexroth ROKIT Locator – Your flexible localization software for manually driven forklifts

We offer you the opportunity to test the Rexroth ROKIT Locator for your application in the field and provide you with support. Please use the contact form to let us know your request.

Real-time location tracking for forklifts

Are you looking for a convenient solution to localize manually driven vehicles such as forklift trucks? With the localization software ROKIT Locator from Bosch Rexroth, the search is over. In a mixed operation with manual and autonomous vehicles, laser localization creates the basis for greater transparency and optimized material handling and warehouse processes. Thanks to the flexible integration options in existing systems, independence from hardware, WMS, ERP and forklift control systems as well as easy commissioning and intuitive use, you can effectively reduce development and application effort as well as the service needs of your end customers with the ROKIT Locator. Rely on proven Bosch Rexroth technology and benefit from localization software that is being used thousandfold by customers in various industries and application areas worldwide.

Laser-based localization and mapping software

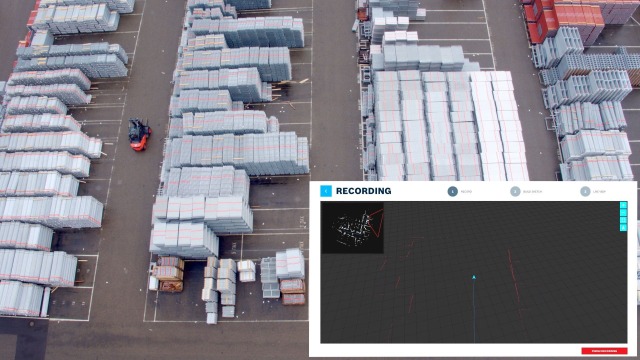

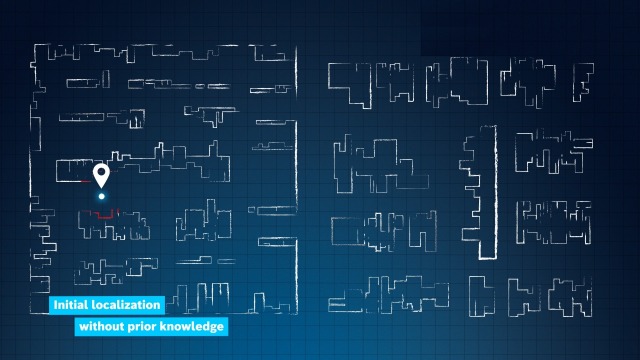

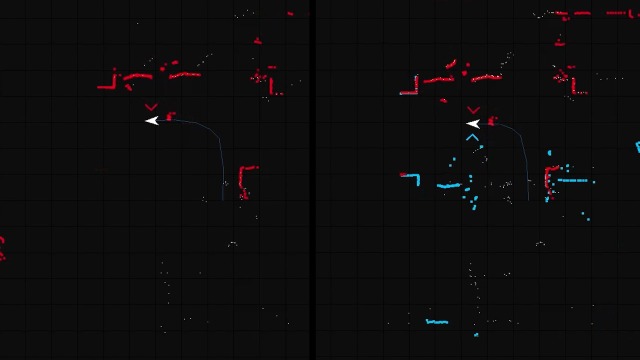

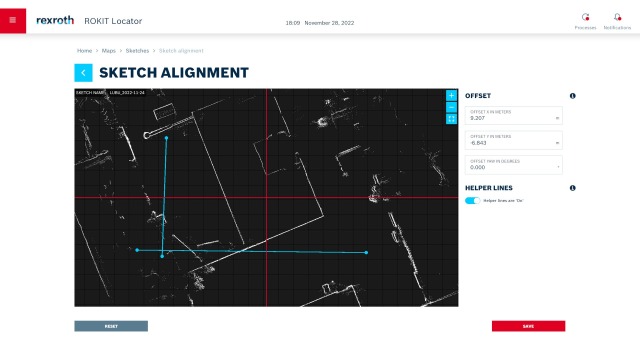

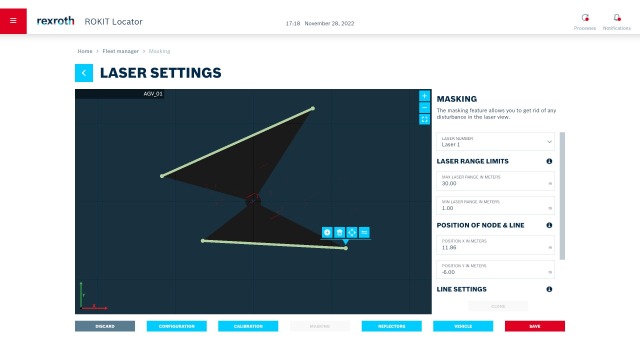

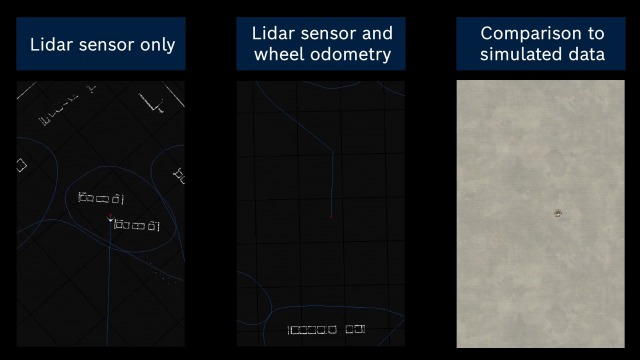

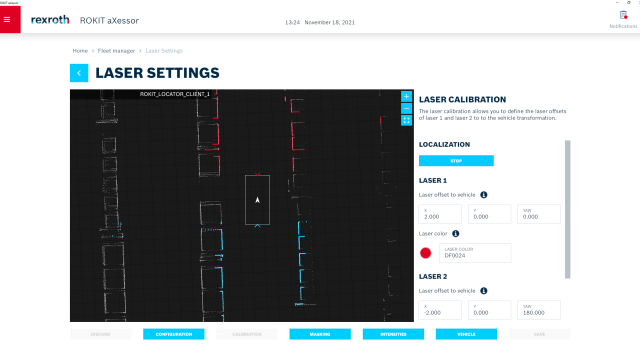

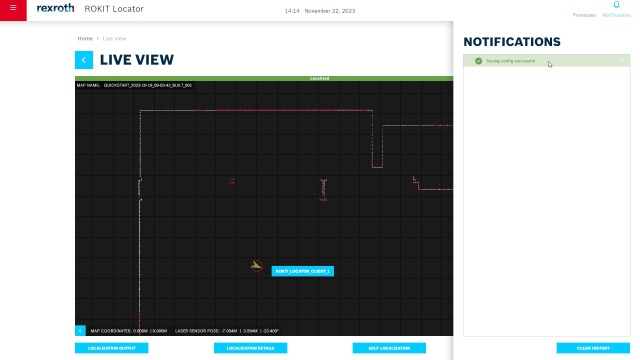

The Rexroth ROKIT Locator is a laser-based software for simultaneous localization of your forklift fleet and mapping of dynamic environments (SLAM). The powerful algorithm uses the information from up to two laser scanners installed on the vehicle to reliably capture and map the natural environment (natural feature navigation). In addition, the real-time location system (RTLS) detects changes in the environment while driving, automatically updates the digital map of the surroundings and then makes it available to the entire ROKIT Locator fleet (automatic map update). Localization is reliable, robust and accurate to within a centimeter – without the use of reflectors or markers. In special situations such as open spaces, additional sensor data such as wheel rotation (wheel odometry fusion) can be optionally taken into account.

Maximize your forklift fleet efficiency

An indoor and outdoor real-time location system (RTLS) of forklifts and goods is the most important prerequisite for position tracking of a forklift and/or AGV fleet management system (mixed fleet). It enables absolute traceability of the forklift and moved goods such as pallets, wire pallet cages or paper rolls (track & trace) as well as automated order picking and automatic inventories, avoids errors during storage and retrieval, and reduces search efforts. In addition, real-time tracking of forklifts offers potential for cost savings and increased productivity through automated scanning processes and a reduction in empty runs.

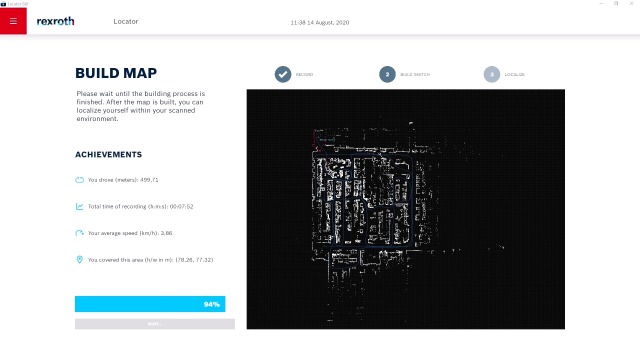

Quick and easy setup

Thanks to fast and easy setup and reliable operation of the real-time location tracking and mapping software, you do not have to worry about determining the position of your manual forklifts. Even after a vehicle restart, due to a shift change, for instance, the ROKIT Locator automatically finds the current position in no time. Additionally, the flexible adaptions to changing environments, such as in block and high-bay warehouses, enable automatic map updates for your entire forklift fleet.

- Equip or retrofit a forklift with a laser scanner of your choice.

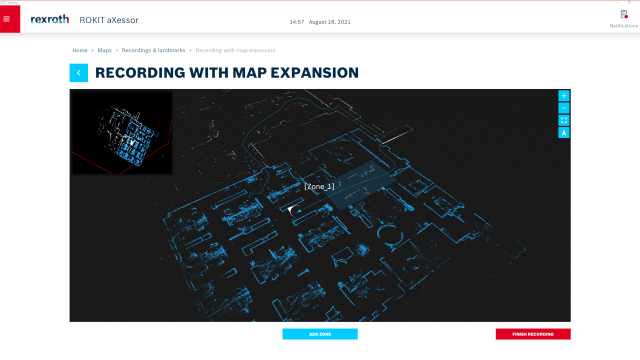

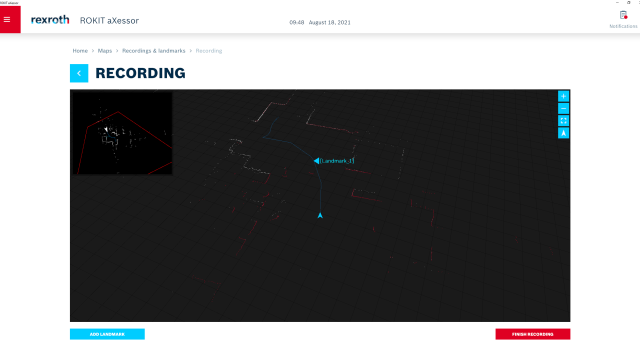

- Set up the ROKIT Locator on any forklift easily and quickly using the aXessor user interface.

- Connect real-time localization to your forklift guidance system (FGS), warehouse management system (WMS), enterprise resource planning (ERP) or warehouse execution system (WES).

- Use the aXessor to visually record a map of the surroundings - immediately all position data is available to the WMS in real time.

Real-time location tracking for forklifts in action

ROKIT Locator.Box – Localization out of the box

Now you have the choice between the pure software solution ROKIT Locator or the ROKIT Locator.Box – ready for use on a compact industrial computer. The ROKIT Locator.Box is designed for convenient and practical integration of our laser localization software into your mobile robots. It consists of a pre-installed and licensed ROKIT Locator software, a fully supported operating system and an industrial-grade, very compact and robust high-performance industrial PC (Pokini F2).

One Pager

Get a first overview of the ROKIT Locator

Request a free trial

We offer you the opportunity to test the Rexroth ROKIT Locator for your application in the field and provide you with support. Please use the contact form to let us know your request.