The Digital Twin of Bosch Rexroth products

Digitalization is crucial today to meet current challenges and ensure long-term competitiveness. At Bosch Rexroth, we offer powerful Digital Product Twins for your products, which help you stay ahead in terms of digitalization.

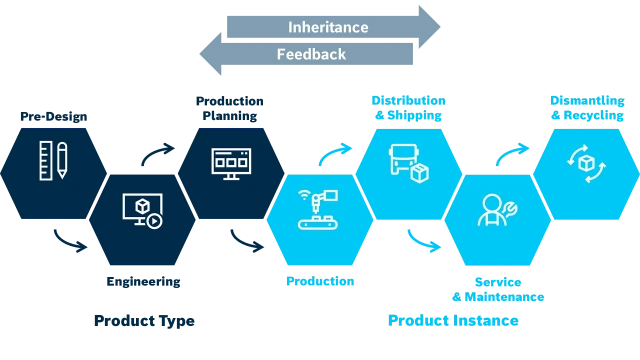

The Digital Product Twin represents a digital image of a real product and reflects various phases of the product lifecycle. It collects all data about a product and makes it accessible. A product can be a single component, a standalone product, or even a complex system throughout its entire lifecycle.

Asset Administration Shell: Your standardized access to digital product data

The Digital Product Twin accompanies each of your Bosch Rexroth products and enables easy integration into your own lifecycle workflows. Based on the Semantic Stack, all relevant product data is bundled according to the standardized Administration Shell (Asset Administration Shell, AAS) and its submodels. This includes the Digital Nameplate of the product as well as its Carbon Footprint, technical CAD data, virtual commissioning data, and much more.

Benefits of the Digital Twin across the Product Lifecycle

Take a closer look at some relevant product data across the lifecycle – provided by our Digital Product Twins.

Efficiency Improvement through Digitalization: The Success Story of HOMAG and Bosch Rexroth

Learn how HOMAG, together with Bosch Rexroth, was able to replace the laborious manual process of master data capture.

What our customers say:

“The standardized provision of master data can significantly reduce effort and errors in our data integration process, making our operations more efficient and reliable.”

(Ernst Esslinger, Director, Center of Excellence)