Motek

Intelligent solutions diversity in the fields of production and assembly automation, feed technology and material flow, rationalisation through handling technology and industrial handling.

Master the challenges of tomorrow? YOU DECIDE.

Intelligent solutions in the areas of production and assembly automation, feeding technology and material flow, rationalization through handling technology and industrial handling – the future poses great challenges for us all.

At our joint stand, Bosch Rexroth together with our Certified Excellence Partners Altmann GmbH & Co KG, DFS Automation GmbH, Heldele Mechatronik GmbH, PTS Group and teamtechnik Industrieausrüstung GmbH will show you our innovative ideas for the Factory of the Future and how we are meeting the challenges of tomorrow.

As local contacts, our CE partner companies offer readily available products and comprehensive service including engineering services. They combine the stability and competence of a large group with the flexibility and agility of medium-sized companies in the immediate vicinity of users.

Be our guest at our booth at Motek 2023 from 10 – 13 October in hall 3, booth 3305 and register here for our booth tour.

We are looking forward to seeing you there.

Smart solution with standard Rexroth assembly and linear motion technology components and a special solution from our Certified Excellence Partner DFS

The station is built with function-integrated profiles and forms the basis. The WP-based system shows a way of reducing cycle times. With the HP2/D special unit, an in-house design of DFS, WP changeover times can be minimized. The whole thing is rounded off with our Smart Function Kit for Handling which was simply retrofitted into the process.

DFS Montageautomation GmbH

Low-cost Smart Item Picking solution

Our certified partner HELDELE shows the simplest way to get picking done. A combination consisting of smart item picking, the toolkit for autonomous handling, an industry cobot from Kassow Robots – including suction gripper and Profinet interface – a ZIVID 3D camera and ctrlX provides solutions for a wide range of processes: goods to robot, batch picking, put wall and conveyor induction. Always in line with the motto of our certified excellence solution partner: HELDELE – your provider of solutions from a single source.

HELDELE Automation

HELDELE Mechatronik

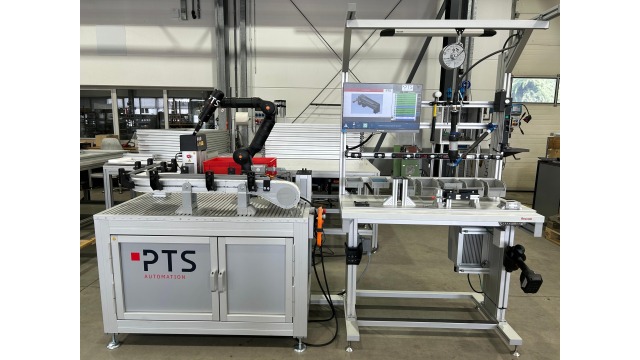

Ergonomic workstations and solutions to meet your needs from PTS

We are your Certified Excellence Partner for automation technology, linear motion technology, tightening technology and hydraulics. We have the solution to meet your needs!

PTS Group

Move heavy parts easily

If heavy parts need to be moved quickly and easily, the teamtechnik rotating table is the ideal choice. Weights of up to 2000 kg can be moved with a turning diameter of up to 2.6 m. Other weights and dimensions are possible on request. The workpiece pallet or product can also be stopped and positioned. With an infinitely adjustable rotation angle of 0-270 degrees and a rotation time of 6 seconds, safety, speed and flexibility are guaranteed – all in accordance with the necessary Industry 4.0 standards. Controlled by the proven ctrlX system from Bosch Rexroth. Compatible with other systems Optionally available with tread protection and sensors.

teamtechnik Industrieausrüstung GmbH

VarioFlow plus chain conveyor system – for vertical and horizontal transport

The VarioFlow plus chain conveyor system adapts to all tasks and ensures that products are transported, distributed and brought together safely. Thanks to the building block principle, individual components and modules can quickly be reconfigured to create new lines. The complete product range includes designs in aluminum and stainless steel as well as fully FDA-compliant materials.

Find out more

ctrlX AUTOMATION

The automation ctrlX AUTOMATION surmounts the classic boundaries between machine controls, the IT world and the Internet of Things and enables modular solutions for the automated assembly line. With the real-time capable operating system Linux, consistently open standards, app programming technology, web-based engineering and a comprehensive IoT connection, ctrlX AUTOMATION reduces components and engineering costs by 30 to 50%.

Find out more

Battery Recycling

Absolutely sustainable. We support the return of valuable raw materials to the manufacturing process - with scalable and economical system solutions. Raw materials account for a large part of the costs in the manufacturing process of lithium-ion cells. Bosch Rexroth solutions designed for efficiency in manufacturing sustainably reduce raw material consumption and costs. At the end of the product life cycle, battery packs are dismantled down to their individual parts. The individual fractions can then be sorted and reintroduced into the cycle.

Find out more

POWER YOUR PROCESSES – Enter a new world of joining technology

Ready for cosmic performance? With the new generation of interactive, connected, and collaborative products in the field of joining and tightening technology, Bosch Rexroth is tapping gigantic potential for your production.

The portfolio, consisting of wireless cordless nutrunners, screw spindle and a control system, convinces with the highest accuracy, reliability and safety in the documentation and evaluation of all data. As a result, the new generation already meets the process requirements of tomorrow today and at the same time creates new standards in daily use – from commissioning to operability and ergonomics to a modern design.

Find out more

Linear Motion Technology – automate sustainable

Do you want to implement linear movements in your applications quickly, efficiently and in a future-oriented manner? Our consistent product range offers you the right solutions for industrial automation: from linear guides, linear axes and screw drives to electromechanical cylinders and integrated measuring systems. Smart mechatronic solutions such as linear robots complete the portfolio.

Find out more

Smart compensation element for robots

Discover new possibilities for your automation. The Smart Flex Effector, our sensor-based compensation unit with independent kinematics in six degrees of freedom, gives robots the feel of a human hand and increases precision. Processes that are difficult to control or can only be carried out manually up to now can be automated, optimized and monitored by simply retrofitting the Smart Flex Effector.

Find out more