One supplier - Many solutions. Design and implementation of turnkey solutions

Our range of products for industrial automation

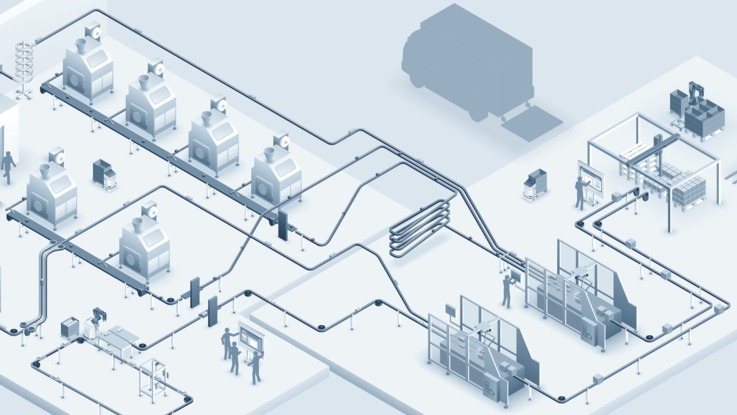

The VarioFlow plus chain conveyor system as the central transport artery is now backed up by the ActiveShuttle autonomous transport systems, theAPAS collaborative production assistants Smart Function Kit for linear motion technology solutions and the fully open assistantss ctrlX AUTOMATION platform. – all of which can be fully integrated into your IT infrastructure.

One supplier. The costs are decreasing. Productivity is increasing.

Proven technologies plus i4.0 components from the market leader

VarioFlow plus

QUIET AND QUICK SOLUTIONS WITH VARIOFLOW PLUS CHAIN CONVEYORS

Quick availability. A few standard modular components in stock allow configuration of various solutions. Reduced spare parts requirements. Flexibility due to multiple combinations. FDA conformity: stainless steel ball bearing with grease approved for food industry. Simple planning, configuration and ordering with a layout designing tool.

VarioFlow plus offers: easy installation, quiet operation, high flexibility and planning freedom

Quick and reliable configuration with the intelligent connection technology and side mounting on a slide rail – optimized gliding properties require only a few drives and provide energy-efficient operation, high drive power and a great degree of planning freedom

ActiveShuttle

INTRALOGISTICS 4.0 – QUICK START-UP, SAFETY ON THE MOVE

ActiveShuttle automates and standardizes your internal flow of materials and goods. In the future, transport your dollies that are loaded with Small Load Carriers (SLC) in a highly flexible and secure manner. ActiveShuttle implements many transport concepts, from cyclical to consumption-based material supply systems. With automated loading and unloading, manual handling tasks are a thing of the past!

Intralogistics 4.0 with ActiveShuttle Management System

Create transparent and efficient internal processes using ActiveShuttle. The ActiveShuttle Management System (AMS) enables highly flexible order management, in which orders can be entered manually or automatically fed via third systems. Get to know ActiveShuttle by first starting your chosen application in the logistics and production area and developing your fleet as required. Adapted to suit your processes. Bring more power to your intralogistics

Automatic Production Assistant (APAS)

CONTACTLESS INTERACTION WITHOUT A SAFETY FENCE

Space-saving automation with free access to all machines: these are the current challenges facing intralogistics. To meet these requirements, manufacturers are looking for compact solutions that can accommodate many machines in the tightest of spaces while being easily accessible. With its collaborative robot with no safety fence, the APAS inline assistant, Bosch Rexroth offers an essential element for automated, integrated logistics solutions with product tracking. The integrated camera means parts are reliably recorded and gripped, thus guaranteeing the secure flow of goods.

Intelligent material flow for Logistics 4.0

With its integrated camera, the robot arm can also detect parts that have not been perfectly fed in, grasp them correctly and place them on a conveyor belt or on a trolley with blister stacks. Bosch Rexroth thus makes continuous material flow possible and closes the gap between its new ActiveShuttle autonomous transport system and its versatile transfer systems.

Smart Function Kit

COMPLETE PLUG & PRODUCE PACKAGE – GET STARTED INTUITIVELY, START PRODUCING MORE QUICKLY

A modular system comprising mechanics, electrics and software. For a wide range of tasks,e.g. joining, pressing or handling. Everything from a single source. Intuitive commissioning, process configuration and operation – without any programming.

ctrlX AUTOMATION

AUTOMATE SYSTEMS MORE INTELLIGENTLY WITH NEW SCOPE OF MACHINE DESIGNS

Software and the Internet of Things are increasingly determining the productivity and flexibility of food and packaging machines. If goods are to be transported, handled and palletized in a clever manner, smart helpers which ensure that processes run smoothly are needed. This is where a real “game changer” comes into play: ctrlX AUTOMATION.

Departure into a new automation world

ctrlX AUTOMATION surmounts the classic boundaries between machine controls, the IT world and the Internet of Things. With a Linux real-time operating system, consistently open standards, app programming technology, web-based engineering and a comprehensive IoT connection, ctrIX AUTOMATION reduces components and engineering costs by 30 to 50%.