Compared to current LED system lamps, they are 50% brighter and use 20% less energy.

And require half the investment thanks to the innovative tri-light configuration.

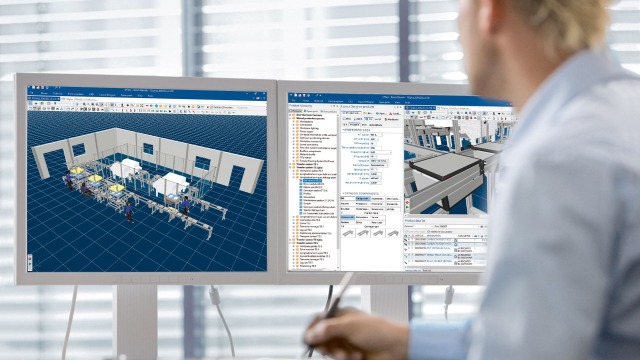

Find the right solutions for your manual or semi automated lines.

SHAPE YOUR LEAN SHOPFLOOR

with Rexroth Manual Production Systems

The main concern of modern production is to avoid waste. The MPS Manual Production Systems from Rexroth have been developed strictly in line with aspects for lean production, enabling simple and fast planning and implementation of lean production installations.

The demands on modern, lean production are more than just focusing on individual modules. In fact, an integrated system with a uniform implementation concept comes to the forefront. At Rexroth, this concept is reflected by the MPS philosophy.