Are you ready for the next

level of mechatronics?

With innovative mechatronic solutions, Bosch Rexroth is following the market trends in factory automation and paving your way to the Factory of the Future. The Factory of the Future will be much more intelligent, flexible, networked and software-based than factories today. It will also become more sustainable and future-proof, because the awareness of the need to use resources more sparingly and of possible effects on the environment is becoming increasingly important.

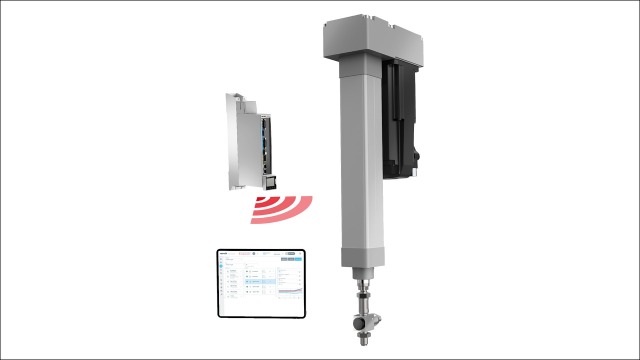

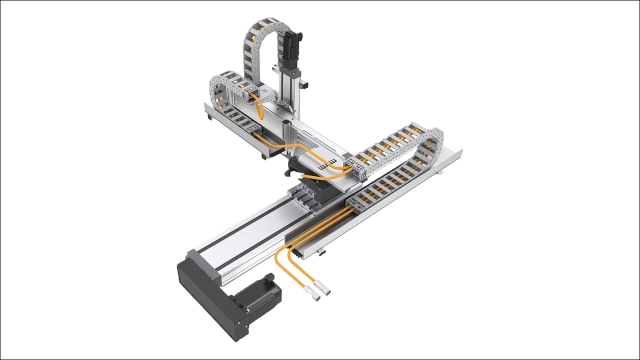

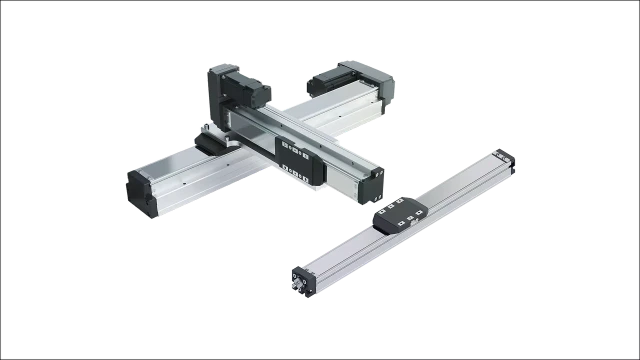

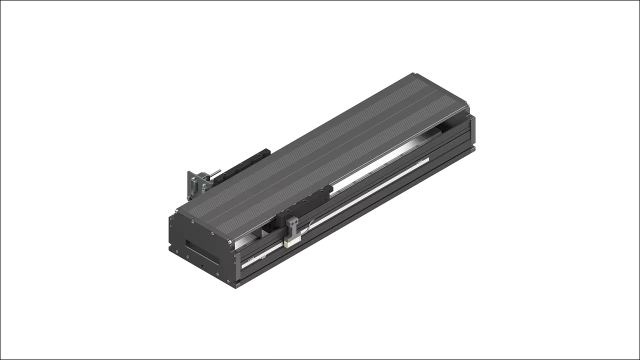

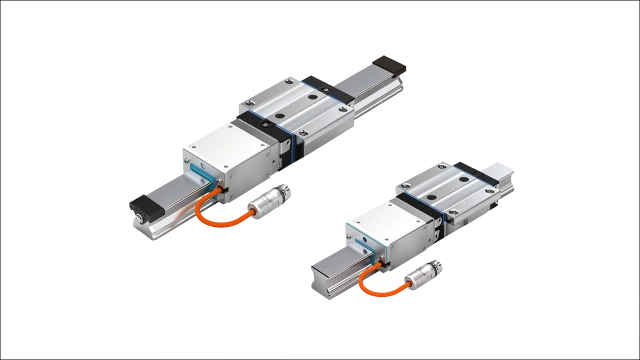

Our linear robots and our smart servo press stand for “Plug & Produce, Perform, Proceed”. Here’s why these three smart benefits are convincing: simplicity and speed from development to the start of production; high operating performance and sustainability thanks to permanent updatability and a flexible use of components and modules.

We’ll make you fit for the Factory of the Future

Are you ready for the Factory of the Future?

Learn more about the mechatronic solutions of Bosch Rexroth.