Cancel

OK

ColombiaEspañol

Seleccione su localización

Industrias

Vista general- Agricultura y Forestal

- Industria de la Automoción

- Producción de baterías

- Industria química

- Construcción e infraestructura

- Bienes de consumo

- Energía y servicios

- Cuidado de la Salud

- Hidrógeno

- Logística y transporte

- Materiales y recursos

- Metalurgia

- Industria farmacéutica

- Reciclaje y manejo de residuos

- Energías renovables

- Semiconductores y Electrónica

- Tecnología de pruebas

- Automatización de almacén y logística interna

Servicio y soporte

Vista generalDescargas

Vista generalCarreras

Vista generalCompañia

Vista generalSoluciones industriales

Vista generalSoluciones para máquinas móviles

Vista generalAutomatización de almacén y logística interna

Vista generalServicio

Vista generaleConfigurators y herramientas online

Vista generalAutomation Community

Vista generalRed de socios comerciales

Vista generalInternational

Cierre de sesión

Seleccione su localización

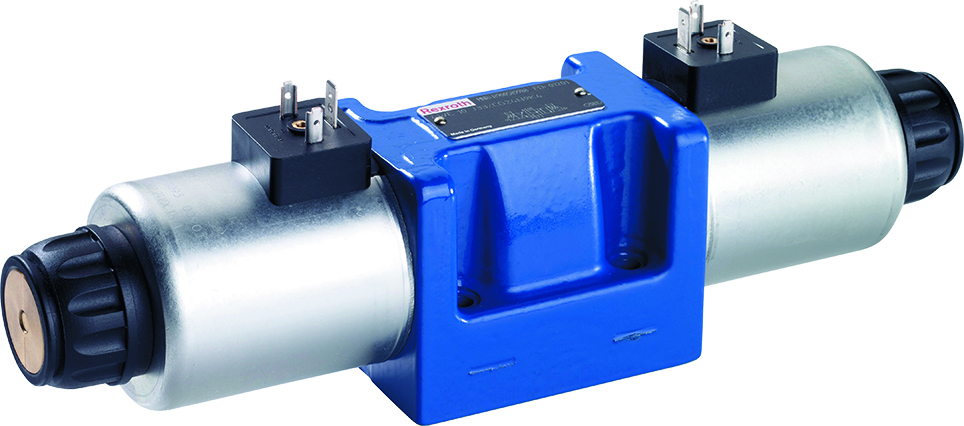

Directional spool valves, direct operated, with solenoid actuation WE 10…E

Consulta de asesoramiento

Código

WE

10

5X

/

E

/

Result count

993 de 993

Main ports

3

3 main ports

4

4 main ports

Type

Directional valve

WE

Directional valve

Size

Size 10

10

Size 10

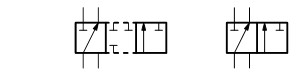

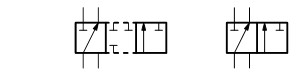

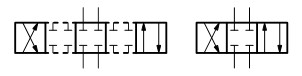

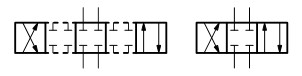

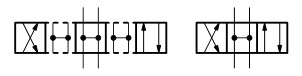

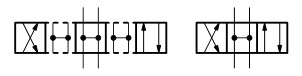

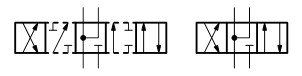

Symbol

A

B

C

D

E

F

G

H

J

L

M

P

Q

R

T

U

V

W

Y

Series

Series 50 … 59

5X

Series 50 … 59

Spring return / detent

With spring return

D

With reinforced compression spring

O

Without spring return

OF

Without spring return with detent

Solenoid version

High-power solenoid, wet-pin, with detachable coil

E

High-power solenoid, wet-pin, with detachable coil

Solenoid voltage

G110

Direct voltage 110 V

G12

Direct voltage 12 V

G125

Direct voltage 125 V

G180

Direct voltage 180 V

G205

Direct voltage 205 V

G220

Direct voltage 220 V

G24

Direct voltage 24 V

G26

Direct voltage 26 V

G48

Direct voltage 48 V

G96

Direct voltage 96 V

W100R

AC voltage 100 V

W110R

AC voltage 110 V

W120R

AC voltage 120 V

W200R

AC voltage 200 V

W230R

AC voltage 230 V

Manual override

Without manual override

N5

With lockable manual override "mushroom button" (large)

N6

With manual override "mushroom button" (large), not lockable

N8

With concealed manual override and protective cap

N9

With concealed manual override (standard)

Corrosion resistance

None (valve housing primed)

J3

Improved corrosion protection

Electrical connection

C4Z

Individual connection without mating connector; connector AMP Junior-Timer

DAL

Central connection, without mating connector; threaded connection 1/2"-14 NPT

DJL

Central connection, cable gland at the cover, with indicator light and cable bridge at the ground connection

DK25L

Central connection, mini-change connector, 5-pole

DK6L

Central connection, central plug-in connection at the cover, with indicator light (without mating connector)

DL

Central connection, cable entry at the cover, with indicator light

K4

Individual connection without mating connector; connector according to DIN EN 175301-803

K4K

Individual connection without mating connector; connector according to DIN EN 175301-803 (coil and sealing element included)

K72L

Individual connection without mating connector, 4-pole with connector M12x1 according to IEC 60947-5-2

Additional options

With additional options

/

With additional options

Switching time increase

Without switching time increase

A12

With switching time increase

Use with flows which exceed the performance limit of the valve (see Product description).

Without throttle insert

B00

B00

B04

B04

B08

Throttle Ø 0.8 mm

B10

Throttle Ø 1.0 mm

B12

Throttle Ø 1.2 mm

B15

B15

B20

B20

B25

B25

B30

B30

B35

B35

B40

B40

Use with flows which exceed the performance limit of the valve (see Product description).

Without throttle insert

H08

Throttle Ø 0.8 mm

H10

Throttle Ø 1.0 mm

H12

Throttle Ø 1.2 mm

H20

H20

H30

H30

Use with flows which exceed the performance limit of the valve (see Product description).

Without throttle insert

R08

Throttle Ø 0.8 mm

R30

R30

Use with flows which exceed the performance limit of the valve (see Product description).

Without throttle insert

N10

Throttle Ø 1.0 mm

Use with flows which exceed the performance limit of the valve (see Product description).

Without throttle insert

X08

Throttle Ø 0.8 mm

X10

Throttle Ø 1.0 mm

X12

Throttle Ø 1.2 mm

X20

X20

X40

X40

X70

X70

Control spool play

Standard

T06

Minimum (to be selected in case of reduced leakage → higher level of oil cleanliness recommended)

T12

Increased (to be selected in case of a hydraulic fluid/environment temperature difference >25 K → increased internal leakage)

Seal material

M

NBR seals

MH

Seals for HFC hydraulic fluids

MT

Low-temperature version

V

FKM seals

Approvals

Standard

CSA

Approval according to CSA C22.2 No. 139-10

Porting pattern

Standard

AN

Porting pattern according to ANSI B93.9 (if solenoid "a" is energized, channel P is connected to A)

Documentación

Add to basket

| You have successfully finished your selection. |

| Número de material: |

Product description

Código:WE105X/E/

| The following data were selected. | ||

|---|---|---|

| Type | WE | Directional valve |

| Size | 10 | Size 10 |

| Series | 5X | Series 50 … 59 |

| Solenoid version | E | High-power solenoid, wet-pin, with detachable coil |

| Additional options | / | With additional options |