Open for Flexibility.

That’s complete factory automation.

Complete solutions to boost fast moving consumer goods productivity

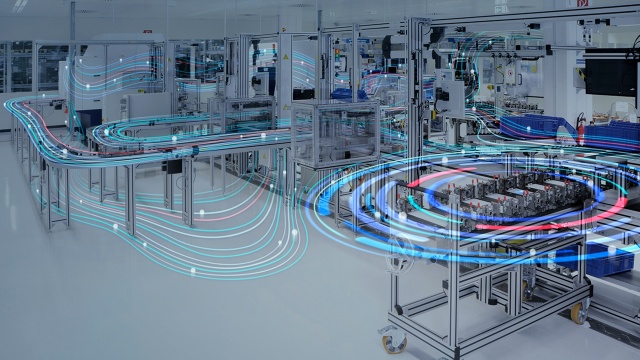

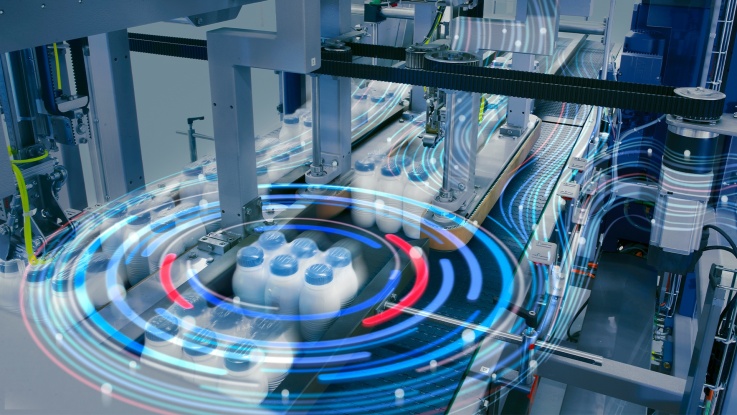

Few industries face the kind of complex, constantly shifting trends and customer preferences that fast moving consumer goods (FMCG) manufacturers deal with daily. FMCG companies prioritize solutions to manufacturing challenges such as supply chain transparency, digital transformation and production line flexibility. Their success and growth demands manufacturing systems that are reliable, highly adaptable and ready to respond to rapid shifts in consumer choices, year in and year out.

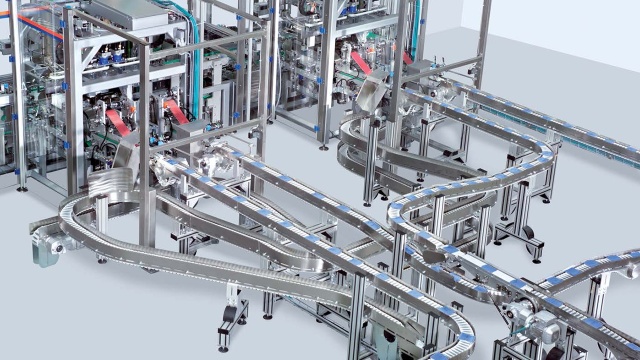

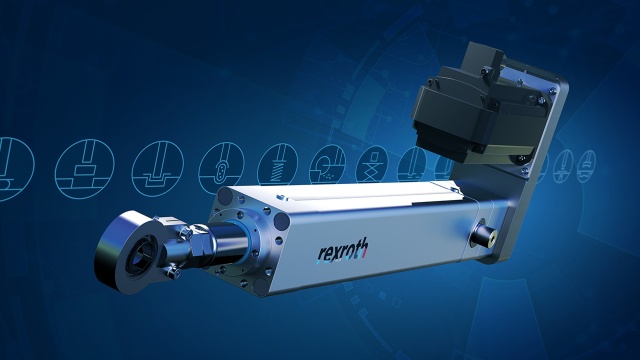

Bosch Rexroth has the industry’s most complete factory automation solutions engineered to meet those needs – proven solutions used in thousands of FMCG operations across the globe. We offer more of the critical automation technology packaging OEMs and manufacturers depend on – controls and drive, mechatronics and material transport, assembly and linear motion technology – fully integrated into complete automation platforms that advance FMCG productivity and flexibility.