Industries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Consumer goods

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

Service

OverviewCompany

OverviewProduct groups

OvervieweConfigurators and Tools

Overview- Home

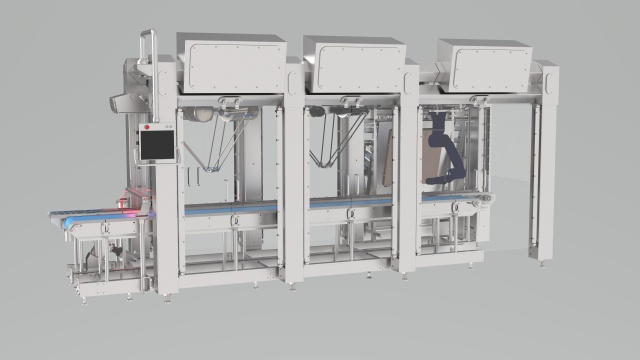

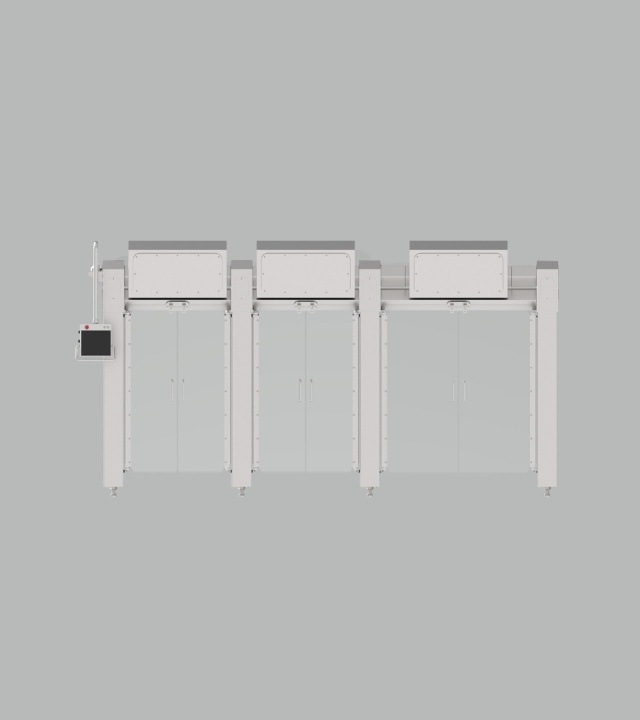

- Robotic systems for FMCG Automation

rexR: Hi-speed Industrial Robots and Robotic Syste

We are the first company in South-East Asia to produce and implement delta robots for high-speed operations in FMCG. With rexR as the service provider for Bosch Rexroth, we help produce and implement industrial robots and robotic systems for automation production processes, packaging and pick & place of consumer goods.

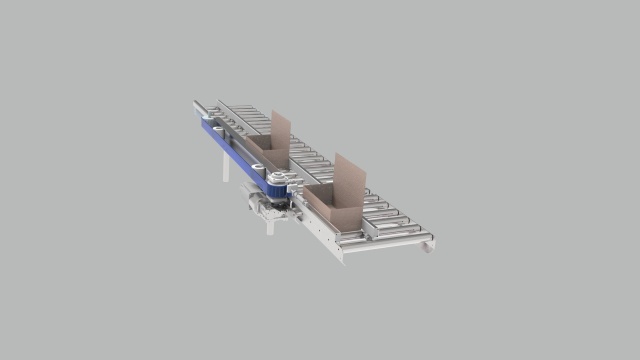

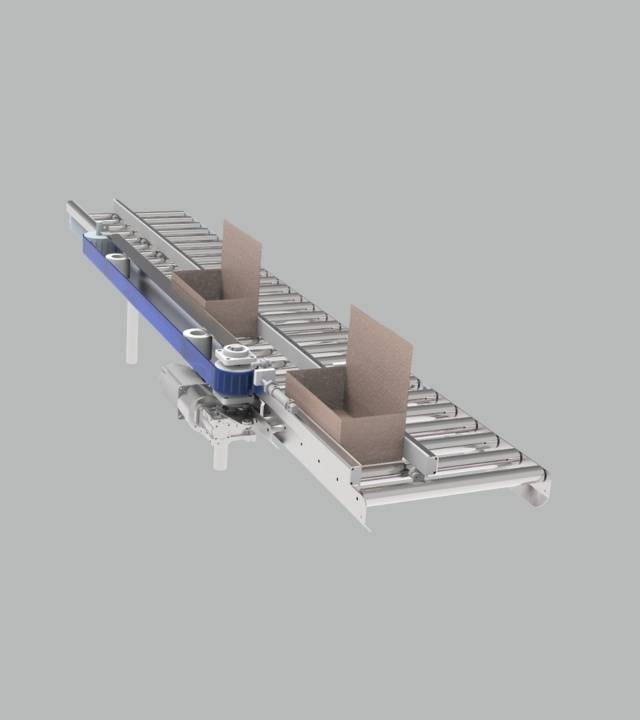

Modules of the robotic system

We use simulation of a robotic system operation in a virtual physical world where the program code is processed and technical economic parameters of the solution are formed. This allows us to accurately simulate the operation of the system and provide the customer with a detailed technical solution.

Why us?

Service

• Standard warranty service period – 1 year.

• The possibility of remote monitoring.

• Annual software update as part of a service contract.

Business case

• Increase production efficiency by reducing the number of personnel providing manual labor

• Significant reduction in the percentage of defects in the production process

• Marginality increase by reducing production cost

• Constant quality of the product

• Low total cost of ownership

• Increase production safety