Factory of the Future Lab

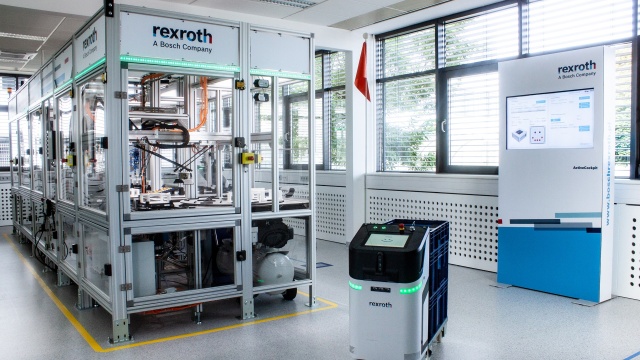

Together with our partners, we have prepared a place on the map of Warsaw where you can get to know, touch and above all, verify the concept of Industry 4.0 live. The Factory of the Future Lab is the part of our showroom CU.BE. Everything that is presented in the CU.BE showroom focuses on discovering technology, deepening knowledge and finding the best way to create an innovative solution with benefits for users (CUstomer BEnefits).

We provide our clients, partners, universities and our employees with a facility that has the ambition to become an active forum for the exchange of everyday knowledge and experience, not only for automation engineers but also programmers, data analysts, process owners as well as suppliers and service technicians of production systems.

We want to implement with you interesting and sometimes even crazy visions that we could not afford in a "normal" factory or in a "real" machine.

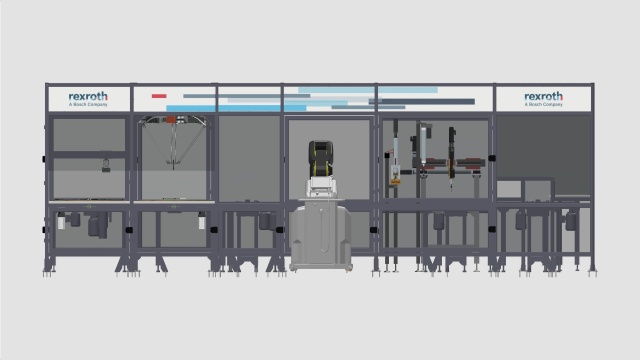

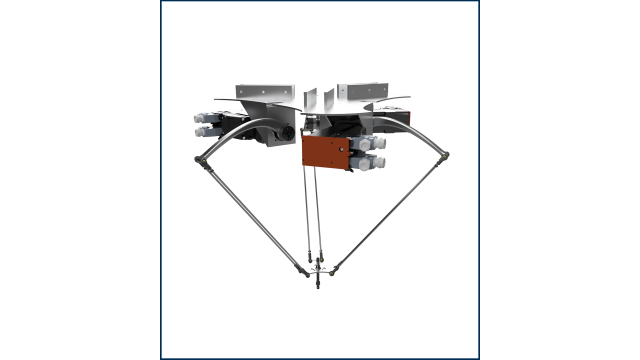

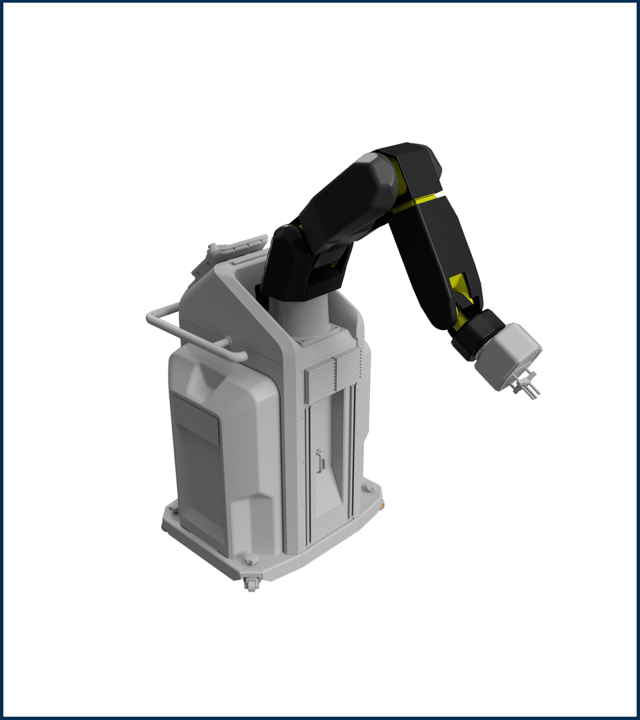

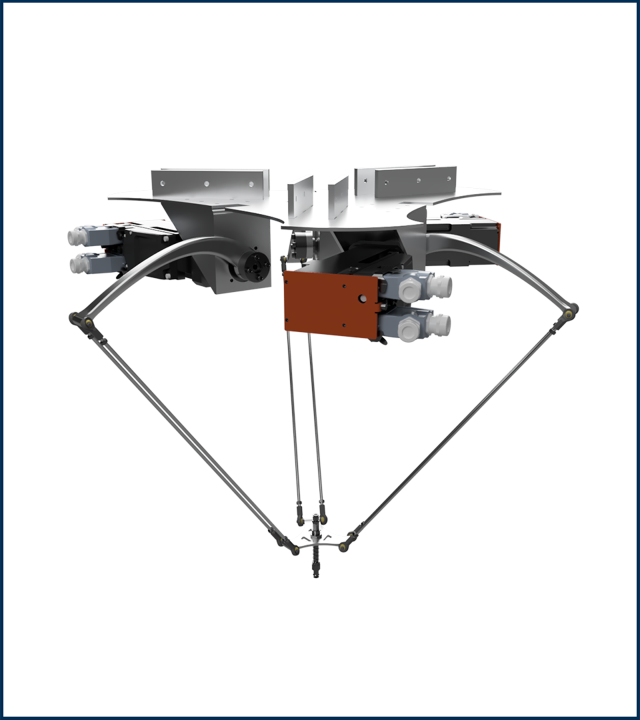

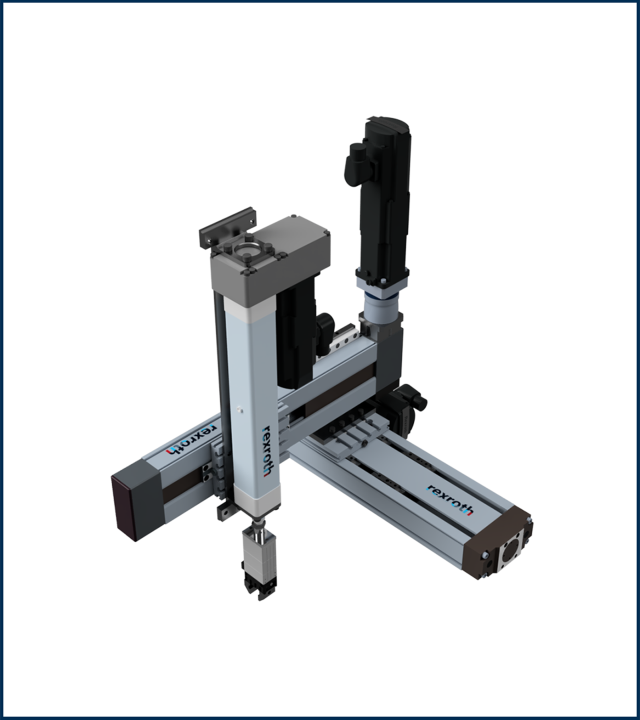

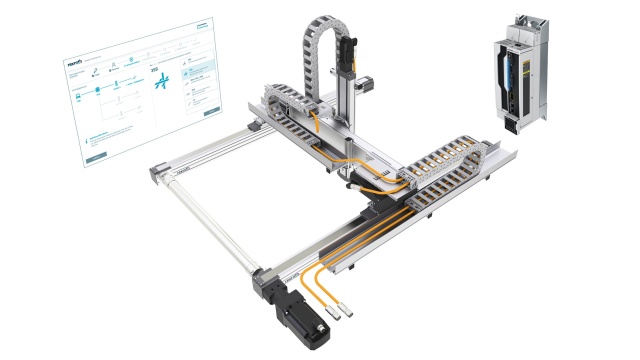

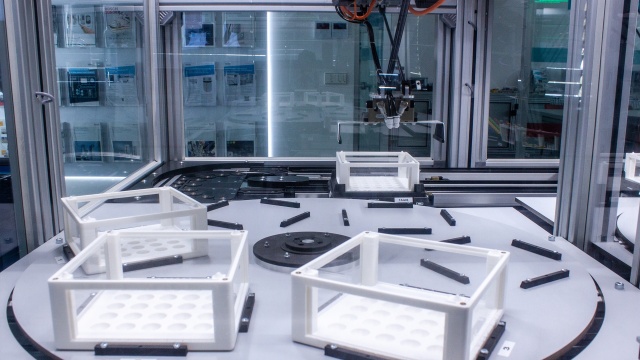

Assembly line created by us consists of 90% of Bosch Rexroth's products and software, e.g: PLC driver, industrial computers, servo drives, inverters, linear displacement technology and assembly technique. Besides them, there are some unusual realisation such as portal manipulator. In addition, implemented autonomous AMR vehicle of the ActiveShuttle family demonstrates sample logistic processes supplying the position in the necessary components. Visitiors can also get to know how to integrate IT world (such as: clouds and analitics systems) with industry by application of modern sensors, protocols and IoT gates. The complement is implementation of idea of product's digital twin, which is used to controlling individual positions and integrating them to one "common organism".

Take a closer look at our assembly line

Discover the detailed construction of the assembly line

Our laboratory is also people

The idea of the demonstration assembly line was realized by the internal forces of our company in Poland together with a team of students from the Warsaw University of Technology. At the beginning, we only thought about a small Industry 4.0 technology demonstration. It could be something locked in a suitcase and visited by customers. However, as the project progressed, we came to the conclusion that to show what the digitization of production looks like, we need to create a larger facility that will also become a training base and laboratory for various automation projects. Today, despite the fact that part of the project team has completed their studies and chose other professional areas, we have designed a great group of specialists at Bosch Rexroth who have successfully developed and are still developing further competences in the digitization of production and modern automation. Together with our partners, who participated in the project, we have created something that we can be proud of, and we cordially invite you to it.

Gallery

Check out our brochure