Mobile & Industrial World

We'd like to invite you to the Mobile & Industrial World, the special place being the part of our new showroom CU.BE. Everything, what is presented in the showroom CU.BE focus on exploring technologies, deepening the knowledge and finding the best way to create innovative solutions with benefits for users (CUstomer BEnefits).

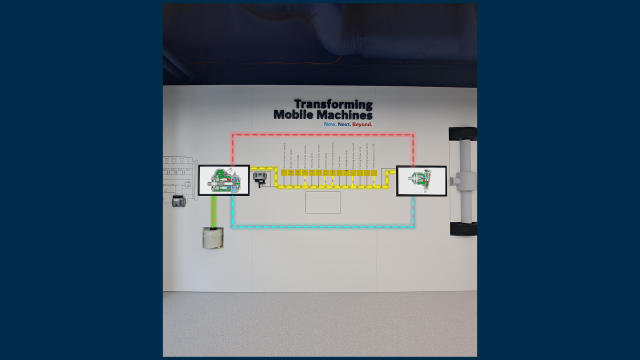

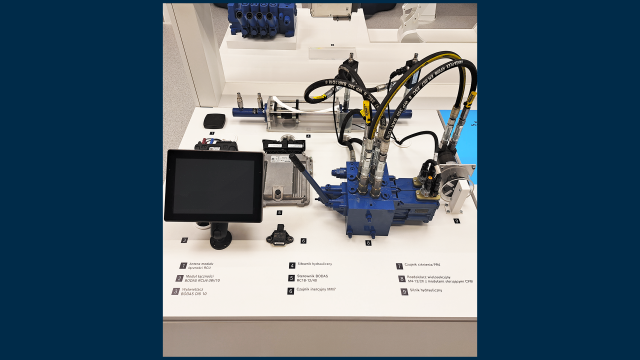

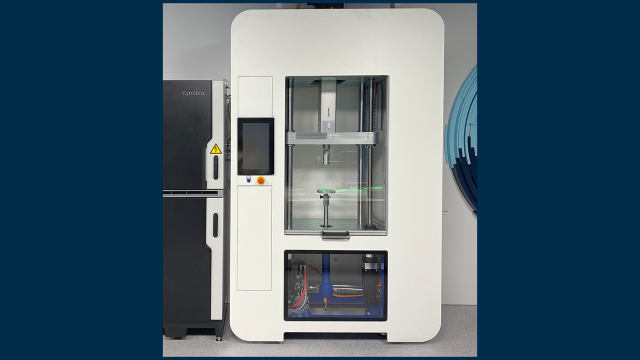

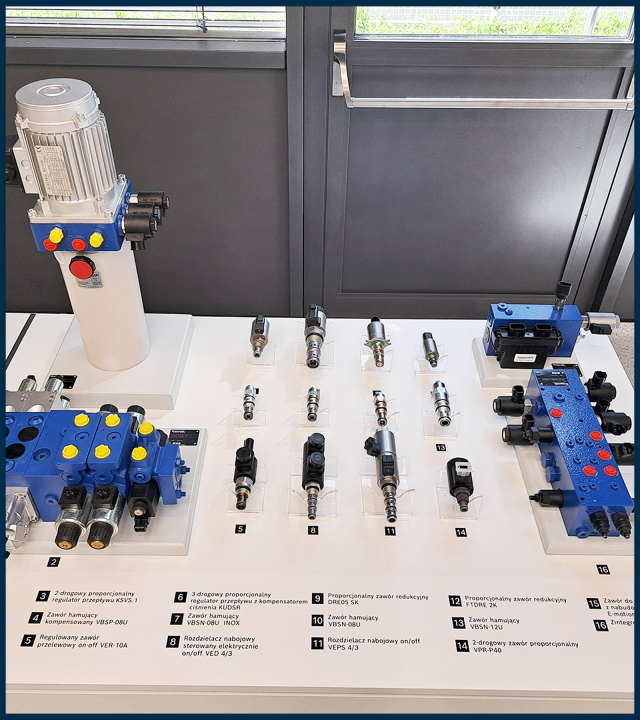

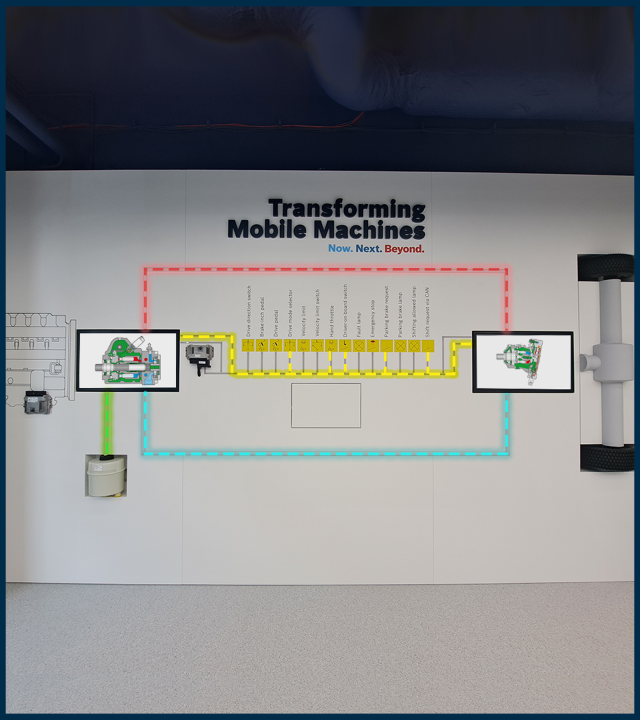

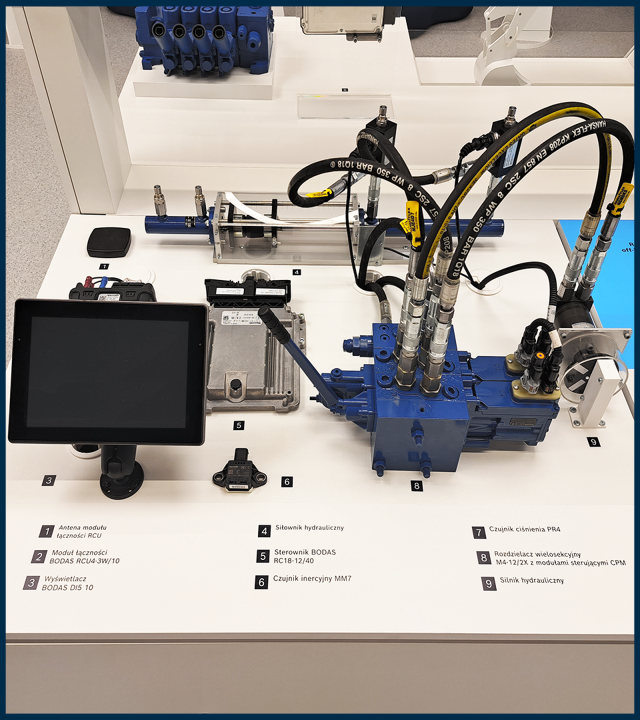

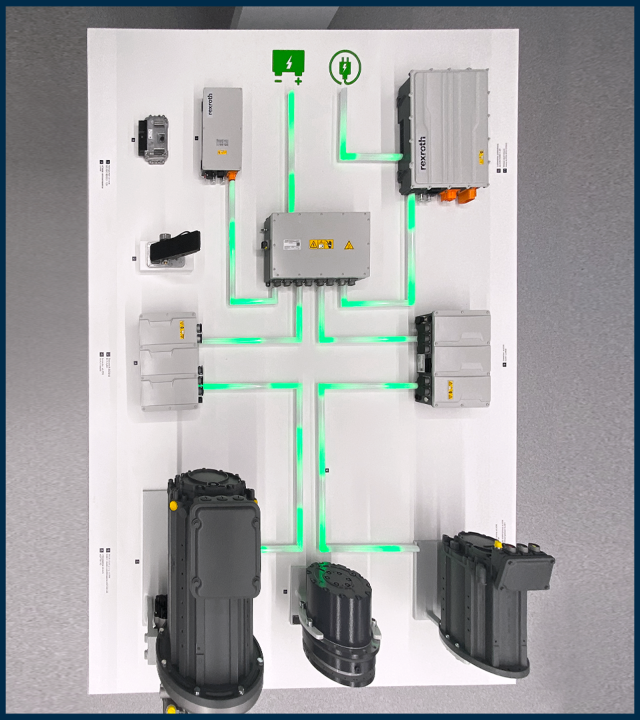

In Mobile & Industrial World we present you exhibits, components and solutions, which are the overview of our new technologies in electrification, electrification, automation and saving energy in one place.

Find out more about presented solutions

In Mobile & Industrial World there are waiting for you e.g: eLION travel drive, a excavator equipped in BODAS, the travel drive eDA system, CytroBox, and an industrial technology demonstation machine. We hope that these will inspire you and help you realize your visions. Through meetings with our experts, you will learn how to improve system performance and make them more efficient while maintaining the highest quality standards.