Products

OverviewIndustries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Consumer goods

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

Service

OverviewProduct groups

OverviewEngineering

OvervieweConfigurators and Tools

Overview

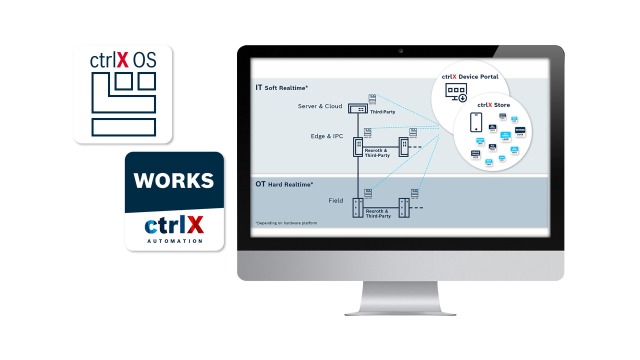

ctrlX AUTOMATION – Motion systems

Motion systems –

seamless material transport in the factory

Automating and optimizing intralogistics processes is a key factor for the success of the Factory of the Future. ctrlX FLOW as a product family offers easy-to-integrate solutions for optimum and highly efficient material and goods flows.