Motek 2022

Motek 2022 - intelligent solutions for automated production The international trade fair Motek, which takes place in Stuttgart from 04.10.2022 – 07.10.2022, is the leading event in the fields of production and assembly automation, feed technology and material flow, streamlining through handling technology, and industrial handling. As such, Motek is the only trade fair to clearly focus on all aspects of mechanical engineering and automation and on the presentation of entire process chains. The consistent target-group orientation is one of Motek’s secrets of success. Focal target groups include automotive, machinery and equipment manufacturing, the electrical and electronics industries, medical engineering and solar production, as well as metal and plastic processing companies in general and their suppliers.

Welcome to Motek 2022

Motek is just around the corner and this year is once again your chance to experience the world of automation from Bosch Rexroth live. Side by side with our strong Certified Excellence partners DFS Montageautomation, Heldele Automation, PTS Automation und teamtechnik, we are driving the digital transformation forward and making you fit for the factory of the future. WE MOVE. YOU WIN.

Visit us at Motek, Stuttgart, Hall 3, Booth 3305

ctrlX AUTOMATION – Two Steps Ahead

The assembly lines of the future are connected, digital and lean. Products are becoming more and more complex, work steps are increasing and cycle times are getting tighter. The automation system ctrlX AUTOMATION meets this core requirements particularly in terms of efficiency.

With ctrlX AUTOMATION, Bosch Rexroth surmounts the boundaries between machine control, IT, and the Internet of Things. With the Linux real-time operating system, open standards, app technology, web-based engineering and comprehensive IoT connectivity, ctrlX AUTOMATION reduces component and engineering effort by 30 to 50%.

The open and flexible system enables the combination of existing and new product lines. This allows users to implement the required modularization, standardization and scalable performance and to tailor it to their individual needs.

The allrounder within the AMR´s - ACTIVE ONE

ACTIVE ONE takes intralogistics to a new level. Intralogistics processes become highly flexible, while being safe and stable. The new generation AMR navigates reliably and precisely even at high speeds of up to 1.4 m/s.

With the omnidirectional driving system, ACTIVE ONE moves effortlessly even through the narrowest gears and in tight, crowded spaces. Extensive sensor technology analyzes the environment in 3D, reliably detects even the smallest obstacles and enables safe operation with people.

The autonomous mobile robot (AMR) ACTIVE Shuttle is already making entry into the factory of the future!

The Factory of the Future is completely flexible and connected – AMRs fit perfectly into this type of environment, delivering goods to the point of need, exactly where and when they’re needed. There’s an increasing demand for multi-variant and small batch production, and ACTIVE Shuttle helps to solve this challenge, making intralogistics processes flexible but without having to change factory infrastructure.

The modular roller conveyor for heavy loads – transfer system TS 7

The new TS 7 transfer system offers everything needed in battery production and is ideal for anyone who needs to transport heavy battery packs weighing over a ton safely and reliably through assembly areas. The system is optimally geared to the special safety and environmental requirements in such areas, allowing large battery packs to be moved on workpiece pallets. The TS 7 portfolio is standardized, has a modular structure and requires minimal maintenance!

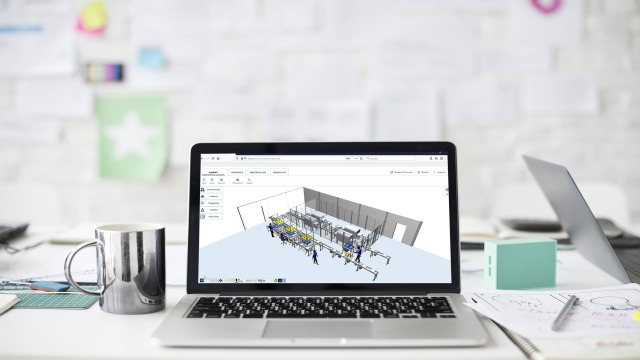

MTpro Online Designer – now create your assembly layouts with the online variant

With the online version of the proven project planning software MTpro for assembly systems, you can now plan independently of time and place. From component selection and configuration to material ordering.

POWER YOUR PROCESSES – Enter a new world of joining technology

Ready for cosmic performance? With the new generation of interactive, connected, and collaborative products in the field of joining and tightening technology, Bosch Rexroth is tapping gigantic potential for your production.

The portfolio, consisting of wireless cordless nutrunners, screw spindle and a control system, convinces with the highest accuracy, reliability and safety in the documentation and evaluation of all data. As a result, the new generation already meets the process requirements of tomorrow today and at the same time creates new standards in daily use – from commissioning to operability and ergonomics to a modern design.

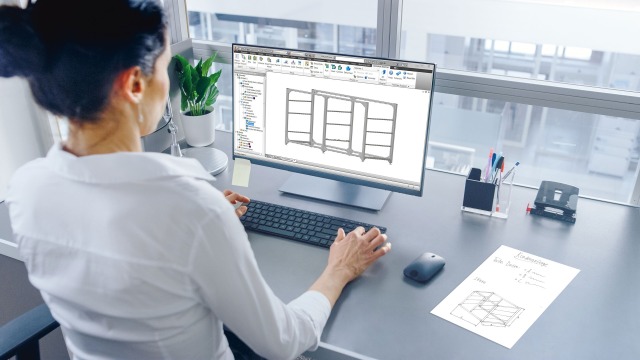

FRAMEpro – the intelligent CAD plug-in

Working with Autodesk® Inventor or Dassault SOLIDWORKS? The CAD plug-in FRAMEpro brings the proven basic mechanical elements from Bosch Rexroth directly into your environment! This saves you a lot of time and avoids potential transmission errors!

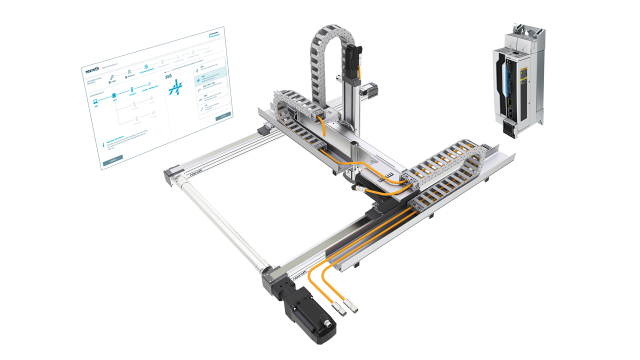

Smart Function Kits - Plug & Produce with the new mechatronic subsystems

The new linear robots - consisting of our best-in-class linear technology components, automation hardware and software - can be used for diverse automation requirements such as joining and pressing, handling or dispensing.

Modern eTools support the product selection. The pre-installed, intuitive operating software enables fast commissioning and simple graphical programming without programming knowledge. The subsystems can be easily integrated into higher-level systems through open interfaces and can be used in a wide range of applications through compatible end effectors.

Smart Flex Effector - sensor-based compensation module for robots

Revolutionize your production and reach a complete new level of automation with our Smart Flex Effector. The sensor-based compensation module with independent kinematics in six degrees of freedom gives robots and Cartesian linear systems the sensitivity of a human hand, thereby increasing precision and opening up completely new areas of application in factory automation. Processes that are difficult to control can be automated, optimized and monitored by simply retrofitting the Smart Flex Effector. Typical applications are joining processes with the marginal tolerances, complex assemblies or difficult handling tasks.

CytroMotion – Driven by Efficiency

The compact self-contained actuator CytroMotion raises the efficiency of hydraulic linear axes in the power class up to 6.2 kW to a new level. With the help of the new compact actuator, linear movements with forces of up to 110 kN can be implemented more compactly, efficiently, and sustainably in a wide variety of machines and systems. These advantages extend over the entire life cycle. Controlled purely electrically, CytroMotion also simplifies engineering and commissioning. The efficient power-on-demand drive and the maintenance-free, hermetically sealed design ensure CO2 savings at minimal operating costs.

Certified Excellence Partner

Together with our partners DFS Montageautomation, Heldele Automation, PTS Automation und teamtechnik, we will present groundbreaking automation solutions for the innovative design of the future in factory automation.