Tire Technology Expo

Tire Expo is a must-attend industry event with exhibits from many of the world's most important suppliers to the tire manufacturing industry

tire technology EXPO 2023

21. – 23.03.2023 Hannover, Germany

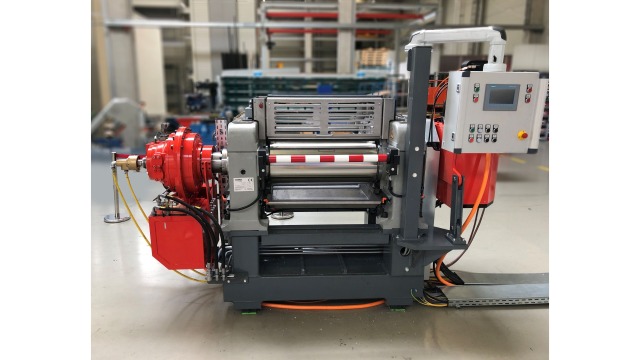

Energy-efficient and Safe: New Hägglunds Drive for Rubber Machines

A new Hägglunds drive specially developed for rubber machines, significantly reduces energy consumption and thus CO2 emissions in daily operation.

The pre-assembled and tested drive units are offered as a plug-and-play solution in six sizes, covering all standard mill sizes.

ctrlX AUTOMATION – automation toolkit for the tire industry

Digitalization is also changing the tire industry – machines and factories are becoming increasingly intelligent. The automation system ctrlX AUTOMATION overcomes the classic boundaries between machine control, the IT world and the Internet of Things and, as a consistently open system, provides all the building blocks for complete automation solutions. The solution is modular, scalable and meets the industry's core requirements for flexibility and compactness. Experience live at our booth how ctrlX AUTOMATION gets automation rolling in the tire industry.

CytroForce – Push your Limits

Bosch Rexroth takes the hydraulic linear drive to a new level of development. The revolutionary solution CytroForce reduces previously space-consuming structures into a smart compact actuator. High performance values, short cycle times and low overall costs lead to a sustainable gain in productivity. Compared to non-integrated hydraulic linear actuator, only half as much installation space is required, and the energy requirement of the variable-speed drive is up to 80 percent lower. The oil quantity is also up to 97 percent lower than in open systems, which is of economic relevance.

The Future starts now – the new hydraulic power unit CytroBox up to 30 kW

Compact, energy-efficient, quit and connected – this is the hydraulic power unit of the future called CytroBox. The unique selling points of the CytroBox are less space requirement - 0,5 sqm instead of 2 sqm - ,saves up to 80 % of energy, reduces oil volume by 75 % and reduces noise emissions by 10 dB(A). The digital service CytroConnect Solutions makes the CytroBox a connected Product. Cloud-based standardized applications provide the user with visualization and evaluation of system status on all connected devices.

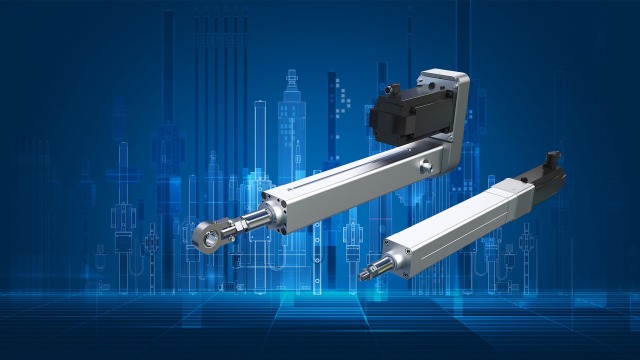

Electromechanical cylinders – reliable and sustainable

It is hard to imagine production without electromechanical cylinders (EMCs). They position, swivel, lift, press, join, punch, crimp and rivet things. And they do all of this in a particular energy efficient manner as they convert the motor torque directly into movement. We offer electromechanical cylinders EMC-HP (High-Power) especially for heavy-duty applications and the harshest conditions. An optional water cooling system also makes it a true endurance runner, even under high forces.

For more information please click here:

New Hägglunds Drive for rubber machines

The presentation will focus on the new Hägglunds drive, offering a comparison in relation to drive characteristics - fixed ratio gearbox and infinitely variable gearbox; energy savings - contribution to energy management DIN 50001; safety - in relation to DIN 1417; digitalization - real acquisition of operational data and contribution to quality management; connectivity - integration of production machines into higher-level process control systems and the basis of communication between production machines; compactness - dimensions and weights; reliability - unstoppable; and cost of ownership - investment cost and maintenance cost, all from a user's view.

Presentation from Daniel Becker, Bosch Rexroth Sales Engineer

The conference is in English only!