Industries

OverviewService

OverviewCompany

OverviewProduct groups

OvervieweConfigurators and Tools

Overview

Electric vehicles are the future – also in industry. AGVs (Automated Guided Vehicles) are gaining ground when it comes to speeding up the flow of materials within companies. However, they do need to be supplied with energy. And that as efficiently as possible. An automated charging device helps to make full use of the potential of industrial e-mobility. With the Quick Charging Connector (QCC) from the company Stäubli Electrical Connectors, high-performance vehicles can be charged extremely quickly without human assistance. In conjunction with ctrlX AUTOMATION and the ultra-compact, high-performance control system ctrlX CORE, significant advantages such as a high power transfer in the shortest possible time result during charging.

Electric mobility is conquering more and more segments, even those beyond classic e-cars. For example, it can be very useful in the mining sector. Here, the switch to electric vehicles could be of great strategic importance because 30 percent of a mine's operating costs can be attributed to the ventilation systems required to extract vehicle emissions. This example shows the wide range of possible applications for electrically powered vehicles.

In industry, AGVs are becoming increasingly popular as a means of transport for handling. As in many other sectors, straightforward, quick loading is needed here in order to keep everything flowing without interruptions and thus economical. With automated logistics processes which take place without human intervention, the energy supply too must be independent. The charging system must also be able to adapt to the existing infrastructure and environment given the high flexibility of AGV processes.

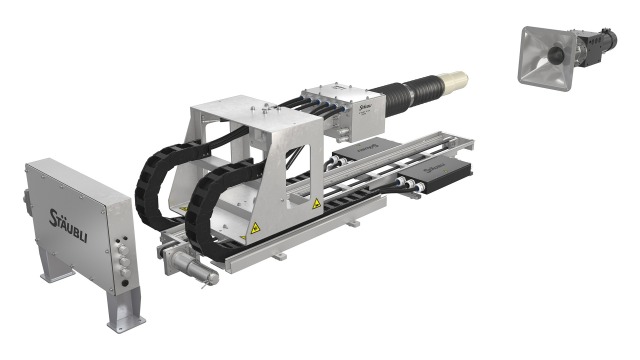

With their automatic quick charging system, Stäubli and Bosch Rexroth provide the solution to this challenge. The Quick Charging Connector (QCC) from Stäubli is designed to meet the requirements of fully electric mobility. It enables high power to be transmitted within a short time, as a result of which the energy storage system can be recharged quickly. This allows, for example, the quiet and emission-free transport of goods by AGV without integrating an uneconomical, large and heavy battery. Thanks to the rapid charging process, the amount of energy to be stored can be reduced. An integrated self-cleaning effect during each plug-in process eliminates the need for time-consuming cleaning and maintenance work, so that high currents can be transmitted permanently.

The automatic charging system communicates not only with the vehicle, but also with the higher-level software for controlling and monitoring the charging process. The control system ctrlX CORE is used here in combination with the compact inverter IndraDrive Cs.

ctrlX AUTOMATION allows the use of industry standards, offers flexibility in communication and ensures long-term availability. Safety requirements are also fully met. With the integration of ctrlX CORE, the quick charging solution can check that the components are connected securely. The safety aspects relating to the large power supply can also be met and managed easily. At the same time, ctrlX CORE makes it possible to compensate for vehicle movements, for example on ferries which are affected by waves.

The automatic quick charging system from Stäubli and Bosch Rexroth is not only suitable for AGVs in industry – it has lots of other uses too. For example, it is also used in a brownfield project in Copenhagen to charge electric boats or provides quick charging for trucks, ferries, buses and many other vehicles.

Because the control system is designed to be open and app-based, new functions can be added to the current solution at any time. For example, the “Firewall” app can easily be installed to ensure secure operation and protection against attacks from outside. Thanks to easily combinable hardware and interplay with apps from Bosch Rexroth and third-party software, the solution offers the modularity and scalability needed to meet all requirements.

ctrlX AUTOMATION thus makes automation much easier and gives manufacturers of electromechanical components for example the opportunity to offer complete turnkey solutions. Accordingly, there are not only numerous areas of application for the quick charging solution – there is also great potential for new business models and more value creation.

Author: Andreas Gryglewski

Function: Head of Consumer Goods & Handling