Industries

OverviewService

OverviewCompany

OverviewProduct groups

OvervieweConfigurators and Tools

Overview

Electrostatic discharge (ESD) can be a costly issue for businesses. Damage to devices alone can add up to amounts from just a few cents to hundreds of dollars...

Electrostatic discharge (ESD) can cause different types of damage to electronic components and devices. These include: Gate oxide / gate damage

Gate oxide / gate damage

Integrated circuits can be permanently damaged by ESD, which causes the breakdown of the gate oxide layer in metal oxide semiconductor (MOS) transistors. It can also damage the thin insulating layers (gate dialectrics) in MOS transistors. This affects functionality and can lead to leakage currents and catastrophic failure of a component or device.

Latch-up

ESD can activate parasitic thyristors inside an integrated circuit, causing a high (and potentially damaging) current flow.

Metallic interconnect

The metal traces on printed circuit boards (PCBs) are also vulnerable to ESD, which can cause localized melting or vaporization of metal traces. This leads to open circuits or short circuits of the PCBs.

Junction breakdown

ESD can result in the breakdown of semiconductor junctions within diodes and transistors, causing permanent damage or degradation of components.

ESD doesn’t always lead to immediate catastrophic failure. There are some warning signs that can indicate an ESD issue with your electrical components or devices. Keeping an eye out for these issues can help a business to identify and address ESD as quickly as possible. These red flags include:

Data corruption

ESD can corrupt digital devices, which lead to random system crashes, corrupted files, and the loss of critical information.

Intermittent problems

Some intermittent issues which have no apparent cause could be the result of ESD. Recurrent, difficult-to-diagnose problems without an apparent alternate cause could be an indication of ESD.

Unexpected equipment failure

One of the most significant signs of ESD is when a piece of equipment performs inconsistently or fails unexpectedly, due to ESD damage to internal circuits.

ESD in production can have a negative impact on electronic components and devices, from gradual degradation to immediate and catastrophic failure. However, ESD risks can be minimized with an ESD protection strategy.

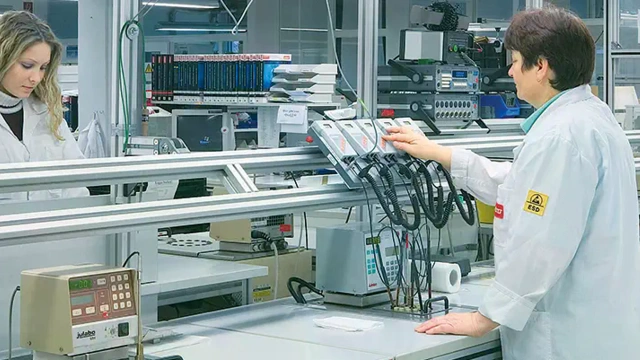

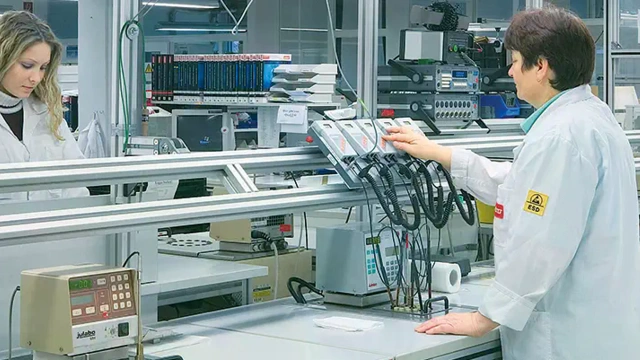

ESD-Protected Workstations

ESD risk aversion strategies can be implemented for the diode, transistor or device, but they can also incorporate manual workstations. Workstations can be designed using materials that limit electrical buildup and discharge and following some simple guidelines, making them static-free. This includes ensuring that all potential ESD sources (equipment, materials, and personnel) are grounded to the same electrical ground point, known as the ‘common point ground.’ Depending on the specific environment, a static-free area may require floor and table mats, wrist bands, heel grounders, air ionizers, or other static-dissipating materials.

International Standard for Electrostatics

The International Electrotechnical Commission (IEC) has created guidelines for best practices to protect electronics from ESD1 . Their recommendations include ‘fundamental ESD control principles’ such as grounding all conductors, avoiding discharge from any charged, sensitive device, and employing ESD protective packaging where necessary.

The International ESD Association outlined six basic principles of static control, which are the recommended areas of focus in the development and implementation of ESD control programs2.

BASIC PRINCIPLES OF STATIC CONTROL

ESD can be a destructive force in any environment that utilizes electronic components: so any factory, warehouse, or manufacturing plant today could be vulnerable to the negative effects of ESD. To minimize the risk of data corruption, downtime, device failure and additional costs associated with ESD, it is critical to understand the types of damage that ESD can cause, look out for red flags to warn of its presence, and take action to protect your business.