Industries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

- Civil Engineering

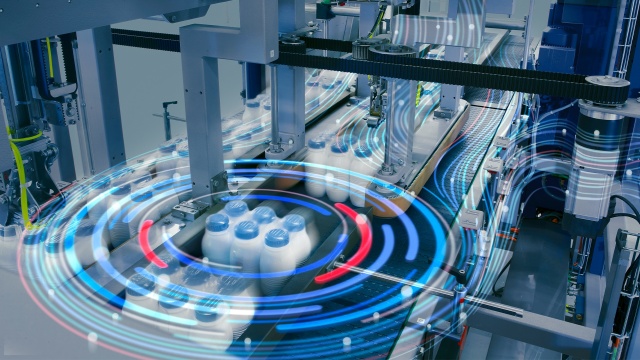

- CPG

- Building Automation

- Warehouse Automation

- Aerospace

- Mining and Minerals

Service

OverviewCompany

OverviewProduct groups

OvervieweConfigurators and Tools

Overview- Home

- Industries

- Semiconductors and Electronics

Accelerate Your Solutions.

Advancing Semiconductor Automation.

Advancing semiconductor automation performance with precision & expertise

700 process steps. Three months from blank wafer to completed chips. 114 billion transistors in a single system-on-a-chip microprocessor. Unprecedented growth in demand. Virtually no other manufacturing process demands the nanoscale accuracy, ultra-precise control and copy-exact technology required to create the chips that are the foundation of our digital world.

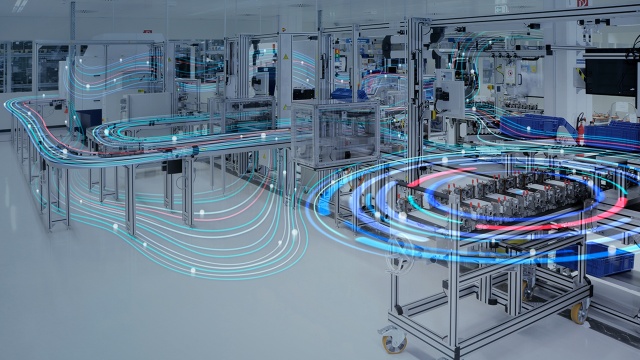

Solving these challenges to create each new generation of chips calls for automation technology with outstanding quality and tool-proven performance. With the industry’s most complete factory automation solutions, Bosch Rexroth has the trusted technology, deep industry expertise, and collaborative relationships to expand your resources and deliver the critical technical performance semiconductor manufacturing demands.

In applications ranging from wafer handling and transport through process chambers to testing and inspection, our efficient pre-engineered assemblies and custom-designed automation solutions give tool builders and fabs the performance they need: ultra-precise movement, nanoscale control and long-lasting operation to sustain the highest levels of production quality and productivity.

Broad cross-technology semiconductor automation portfolio

Open, compact, extremely precise

Nanoscale-accuracy and virtually vibration-free movement are key precision requirements for semiconductor tools. Our revolutionary ctrlX AUTOMATION platform and our expanding compact servo drive family provide the powerful, proven motion control technology that drives our automation solutions with:

- A Linux real-time operating system

- App-based programming technology

- Full support for EtherCAT

- Web-based engineering

- Advanced authoring tools for semiconductor applications

Smart MechatroniX: Smarter handling solutions

Semiconductor tool gantry handling systems need efficiency, stability and ease of integration. Our Smart MechatroniX systems combine proven linear motion components with smart, easy-to-program controls to deliver torsion-free positioning with high accuracy through:

- Simplified engineering and tool integration

- High-dynamic, high-precision coordination of two axes

- Maximum contour control through real-time synchronization

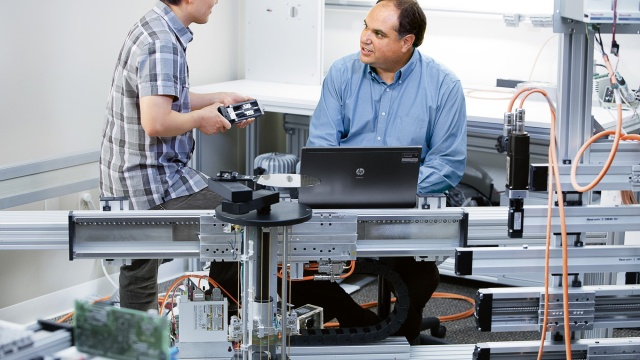

Fully integrated and tested mechatronics

Complete mechatronics solutions with all the technology from one supplier: That’s the unique value Bosch Rexroth brings to custom mechatronics subassemblies. Through smart, well-engineered integration of linear components and electronic motors, controls and sensors, you reduce your in-house engineering efforts because we supply:

- A wide range of precision linear modules

- Controls and drives configured for semiconductor applications

- Deep expertise engineering complete mechatronics

- Complete subassembly configuration and testing operation

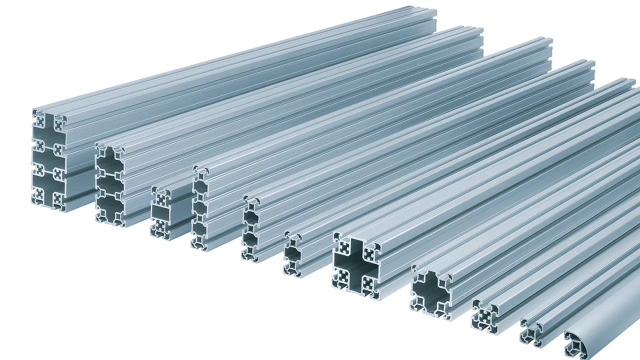

Frame Your Factory

Bosch Rexroth's aluminum profiles are used to construct robust and customizable workstations, machine frames, and protective enclosures that are essential in semiconductor production environments. Our aluminum profiles help maintain the stringent cleanliness and safety standards required in semiconductor manufacturing, contributing to efficient and high-quality production processes.

- More than 120 different profile cross sections

- Fine profile grid graduation for economical profile selection

- Stable profiles with high load values

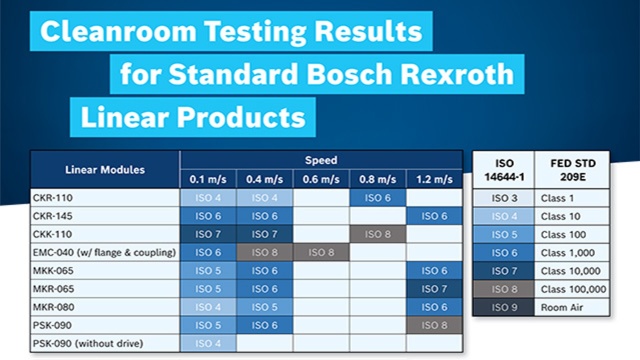

Linear motion: Continuous innovation for precise motion

Even the slightest vibration when wafers are in motion can harm chip quality. By constantly updating our range of innovative linear axes, we refine the efficiency and stability of all our linear motion products and modules. As an industry leader and innovator for over 30 years, we’ve constantly enhanced our portfolio to feature:

- Profiled rail systems

- Linear bushings and shafts

- Complete ball screw assemblies

- Precision linear modules, such as the PSK Gen 2