Industries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

- Civil Engineering

- CPG

- Building Automation

- Warehouse Automation

- Aerospace

- Mining and Minerals

Service

OverviewCompany

OverviewProduct groups

OvervieweConfigurators and Tools

Overview- Home

- Products

- Product groups

- Linear Motion Technology

- Subassemblies

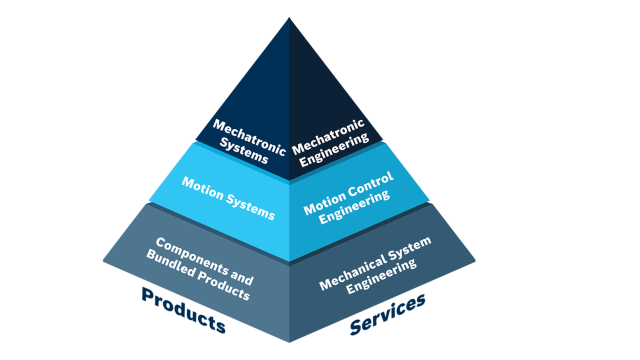

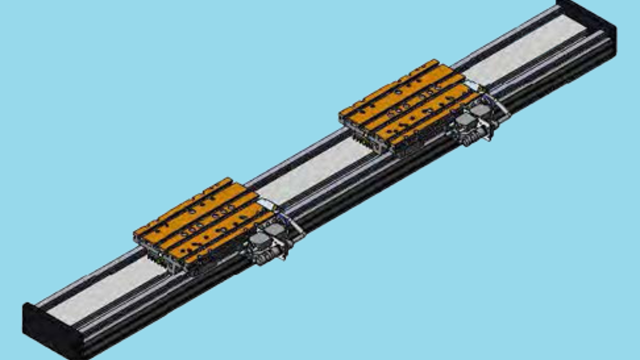

Mechatronic subassemblies play an integral and valuable role in a non-stop manufacturing world.

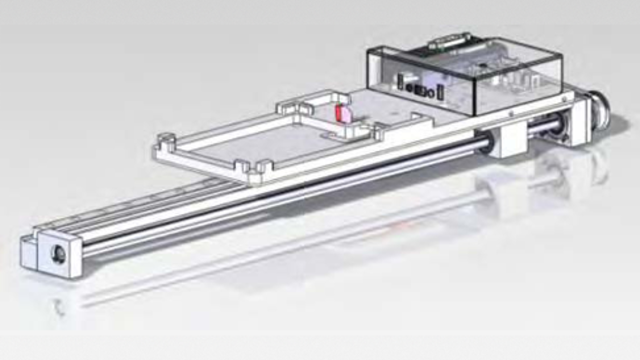

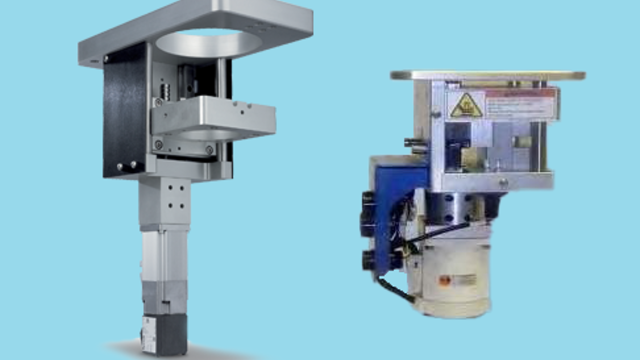

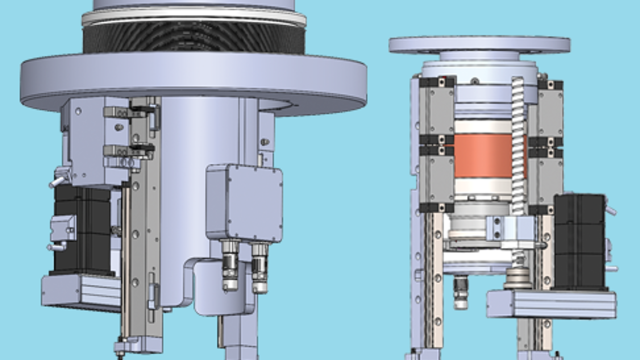

Through smart, well-engineered integration of linear components and electronic motors, controls and sensors, subassemblies provide complete solutions that make it easier for machine builders to quickly build complex manufacturing systems for demanding industries ranging from pharmaceutical packaging to semiconductor fabrication.

To ensure that our mechatronic subassemblies satisfy all requirements, Rexroth has created a complete subassembly configuration and testing operation with state-of-the-art production equipment and quality processes.