Products

OverviewIndustries

OverviewService

OverviewBuy

OverviewCompany

OverviewProduct groups

OverviewEngineering

OvervieweConfigurators and Tools

OverviewEDI (Electronic Data Interchange)

Overview

In order to make shipping more environmentally friendly, crude oil residues should no longer be burned in ship engines in the future. Some refineries recycle it further in a closed process, for which the petroleum coke must first be crushed. Together with Bosch Rexroth, Jülch GmbH has come up with a reliable solution for this difficult task.

Sometimes, climate protection requires a special effort. For example, when it comes to crushing lumps of petroleum coke up to one meter in size in a refinery in order to make them transportable for further processing and then make them available to end customers. Jülch GmbH, a mechanical engineering company based near Karlsruhe, specializes in this crushing process and has found a market niche for itself with technological support from Bosch Rexroth.

Petroleum coke is a waste product resulting from the thermal cracking of crude oil. Because the tough black mass hardens within a few hours and can then no longer be cut by water jet, the crushers at Jülch GmbH must be ready for use at all times. The pair of rollers mounted in them breaks the large lumps at up to 70 revolutions per minute. After crushing, the water-coke mixture is pumped into a container where the water is removed. Once processing is complete, the dry petroleum coke is ready for loading.

The closed process means that even the last residues are returned to the value chain instead of being burned in ship engines as was the practice in the past. Thanks to this environmentally friendly alternative, fewer toxic substances and greenhouse gases are released into the environment. In addition, harmful particulate matter is no longer released, which helps to protect the health of refinery employees.

Jülch’s expertise lies in its ability to reliably crush the petroleum coke under the prevailing environmental conditions. “This is only possible with highly robust hydraulic drives that produce extremely high forces, especially during start-up,” said Managing Director Felix Jülch. “The rollers must also process the whole batch. Otherwise, the petroleum coke would harden, could no longer be cut and would bring the refinery process to a standstill. Naturally, this must not be allowed to happen.”

Jülch GmbH realized that a hydraulic drive is the only viable option after an initial solution with electric motors failed owing to the high loads and the dusty operating environment. According to the findings from the early development phases, the enormous forces involved require a drive that is as durable as the entire machine. The robust design of the crushers is demonstrated, among other things, by their walls which are up to 80 mm thick and have a total weight of over 60 tons, with the rollers alone weighing in at ten tons each.

For Felix Jülch, the reason why Bosch Rexroth was chosen as the drive partner is obvious: “The Hägglunds radial piston motors from our partner offer unique performance characteristics. With Bosch Rexroth's expertise when it comes to heavy hydraulics, we were able to come up with high quality machines and meet the high demands as regards system reliability.”

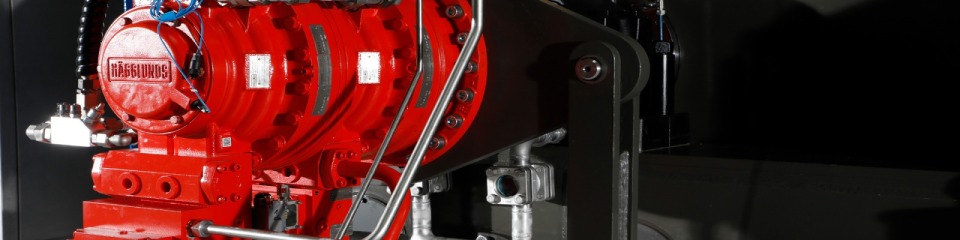

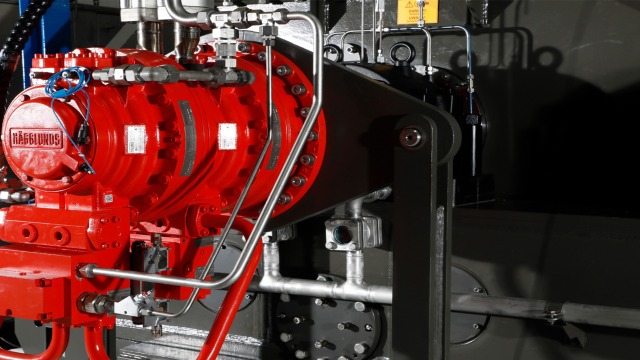

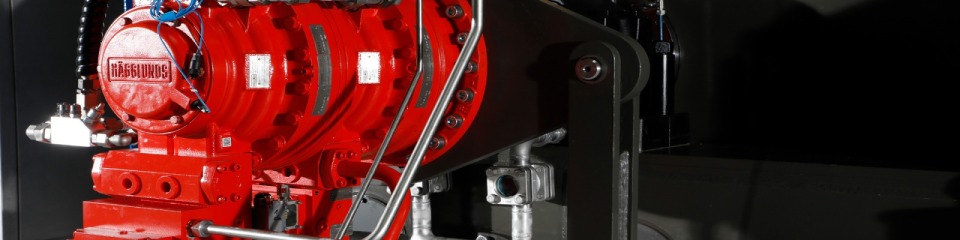

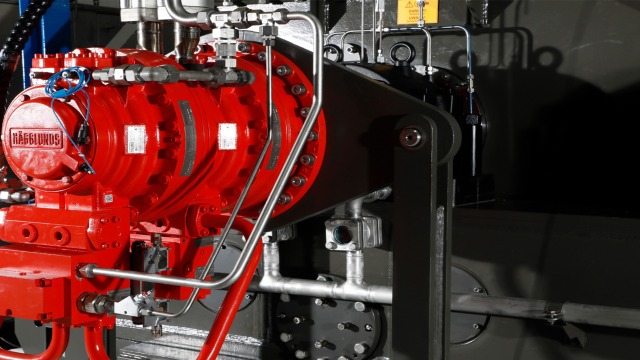

Complete hydraulic system for EX zone 2: The Jülch petroleum coke crusher with tandem motor, power unit and control system including condition monitoring. (Image source: Jülch GmbH)

Each of the two pairs of rollers has a tandem drive combining a Hägglunds CA radial piston motor of nominal size 210 with a second one of nominal size 70. The smaller one is switched on only during start-up, increasing the starting torque by over 40 percent. This allows the lumps of coke to be crushed safely even if they are wedged after falling into the crusher. Bosch Rexroth supplies the complete drive system – including functional control, pumps and the hydraulic supply. Because the machine works in the EX zone 2, all system components are ATEX-compliant. Bosch Rexroth also provided assistance with the necessary documentation.

The petroleum coke crushers from Jülch GmbH are designed to last for at least 20 years. The first system set up in Germany has already been running longer than this. Apart from the scheduled replacement of wear parts or the exchanging of individual motors for overhaul, there were no shutdowns.

According to Felix Jülch, the customers of the machines subsequently built for other international refineries are also very happy. And this despite the fact that each site has its own unique environmental conditions, e.g. very low temperatures in winter, which are taken into account on a customer-specific basis when designing the crusher. “Thanks to the support from Bosch Rexroth and the configurability of the Hägglunds control system, we were able to ensure smooth operation for each machine.” The machine manufacturer was able to rely on global support during commissioning too.

The roller drive and power unit are monitored to prevent unplanned downtimes. The sensor data collected in the machine for speed, oil level, pressure and temperature are sent to the control room via an interface. If specific limit values are exceeded the condition monitoring triggers an alarm. “In the event that a motor has to be switched off, which has not occurred so far, the system is dimensioned in such a way that the current batch can be finished with a single roller,” said Felix Jülch.

The petroleum coke crushers developed jointly with Bosch Rexroth enable refinery operators around the world to meet their environmental requirements more easily and actively protect the environment. Accordingly, there is great interest in these systems with the reliable Hägglunds drives.

According to Felix Jülch, the technical solution, the constructive partnership and the short response times of the Rexroth team are crucial for the success of the project. “We can rely on the commitment of our hydraulics partner just like we can on the robustness of the hydraulics. Both provide a sound basis for further development.”

Wolfgang Ehmke works in Sales Central Europe within the Large Hydraulic Drives Business Unit, Bosch Rexroth AG. As a customer service representative in the field with a focus on the chemical industry, he is an industry expert within Sales Central Europe.