Products

OverviewIndustries

OverviewService

OverviewBuy

OverviewCompany

OverviewProduct groups

OverviewEngineering

OvervieweConfigurators and Tools

OverviewEDI (Electronic Data Interchange)

Overview

The Bosch plant in Bamberg manufactures spark plugs using state-of-the-art hydraulics. An upgrade with the stand-alone CytroBox unit increases productivity and reduces energy consumption by 59 percent.

120 years ago, the first spark plug was used in a car. The key component for gasoline engines invented by Robert Bosch is today manufactured at the Bosch plant in Bamberg using state-of-the-art methods for the world market. The automotive supplier, which has been operating in a climate-neutral manner since 2020, not only pays attention to process reliability, but also to the smallest possible CO₂ footprint. For industrial hydraulics, this means that it must become increasingly intelligent and sustainable.

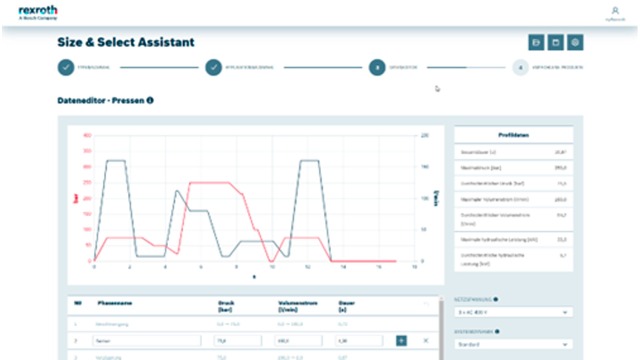

Panat presses driven by the CytroBox: The intelligent oil supply ensures a precise pressure profile and reduces energy consumption.

The latest modernisation project for more energy efficiency concerns six presses in a short-cycle production line. Each press has 5 Panat (conductive glass filling) drive and press it under high pressure (135 bar) with the ceramic housing of the spark plugs. When the stroke lengths and flow rates of the presses had to be increased in the course of a product expansion for longer types of candles, the production planning seized the opportunity to renew the hydraulic unit. Instead of the conventional assembly with large hydraulic accumulator, the cylinders were replaced by the intelligent stand-alone solution CytroBox from Bosch Rexroth.

From a conventional point of view, stand-alone units like the CytroBox play in a completely new league: They are not only compact and quiet, but also intelligent and save energy and CO₂ emissions. Because they do not require electrical installation, additional sensors, sound insulation or a separate oil sump, the installation effort is not comparable to previous practice. Only power supply, hydraulic hoses and line control must be connected. This is managed by a software wizard and is done after a few minutes.

Generation change: The Bosch plant replaces old units with the smart and fast-to-implement stand-alone solution CytroBox.

The CytroBox is well received at the Bosch plant in Bamberg, because it was possible to achieve the goal of a process-reliable and at the same time smart pressure supply efficiently in half the area. The finely controllable electrohydraulics make an important contribution to quality assurance, as it ensures a precise pressure profile with rapid pressure build-up and thus reliably prevents pressure overshoots or overloading of the system.

Thanks to the modular design of the CytroBox, important safety functions such as emergency stop can also be easily and cost-effectively mapped via optional modules. The line integration was also quick thanks to standardized interfaces. The fact that the CytroBox can be networked well - a basic requirement for modern production - was also very popular. Last but not least, the CytroBox with pre-installed technology for condition monitoring provided a solid basis for continuous process improvement and predictive maintenance.

Through simulation and calculations in advance, Bosch Rexroth dimensioned the CytroBox in such a way that the previous storage system was no longer necessary.

The flow-optimized design of the CytroBox and its variable-speed drive with energy-on-demand principle have reduced power consumption by 59 percent. Among other things, it is essential for the savings potential that the precisely controllable displacement control generates pressure only when the pressing cycle requires it and otherwise goes into energy-saving stand-by operation. Another advantage of the intelligent interaction of servo motor, pump and block produced with 3D sand core printing are the line operators, the CytroBox works so quietly that it can hardly be heard even in the immediate vicinity.

The power unit from the Connected Hydraulics portfolio from Bosch Rexroth also convinced the plant management in terms of reliability. Group leader Daniel Link states that he has not heard anything about the CytroBox since the installation". From the point of view of a production manager, this feedback is probably the greatest praise for a hydraulic unit and its inventor.

After the positive experience, the Bosch plant plans to soon modernize further lines, including the smaller compact unit CytroPac. The partnership with Bosch Rexroth will thus become a further building block for fully networked and low-CO₂ production.

Ready for monitoring: The prepared CytroBox enables the Bosch plant to perform predictive maintenance and continuous process improvement.