Industries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Consumer goods

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

Service

OverviewCompany

OverviewProduct groups

OvervieweConfigurators and Tools

OverviewBRRTC Trainings

Overview- Industry Specialist AHK i4.0

- Practical Approach of Open Software Controllers in Advanced Manufacturing

- PoC

- Practical Applications of Condition Monitoring

- Essentials of Basic Networking, Database and Web Applications for Advanced Manufacturing

- Introduction and Applications of Industry 4.0 for Advanced Manufacturing

- Contact Form Embark Your i4.0 Journey

- Data-driven Connected Hydraulics in Advanced Manufacturing

- Implementing Automation Technologies in Smart Factory

- Home

- Factory Automation

- Battery Manufacturing Automation

Open for Scalability.

That’s complete factory automation.

Battery Manufacturing Automation

Move battery manufacturing forward – fast

From pacemakers to smartphones to EVs, the electric battery has become undeniably essential to modern life. Battery manufacturers are seeking smart, adaptable manufacturing solutions to help solve complex process challenges and stay flexible as battery technology develops and demand surges.

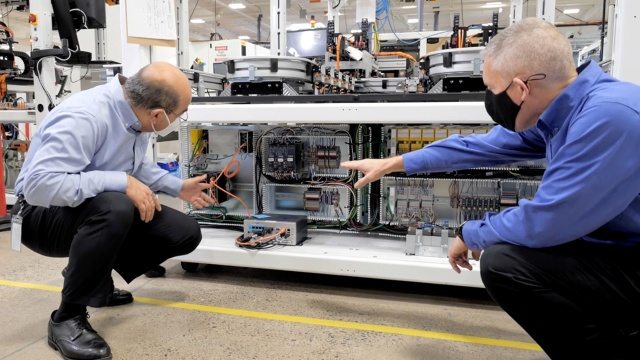

Bosch Rexroth is ready to meet those challenges, combining deep battery manufacturing expertise with complete factory automation solutions, tailored to meet complex battery production requirements (heavy loads, clean room/dry room conditions, no metal or copper, etc.).

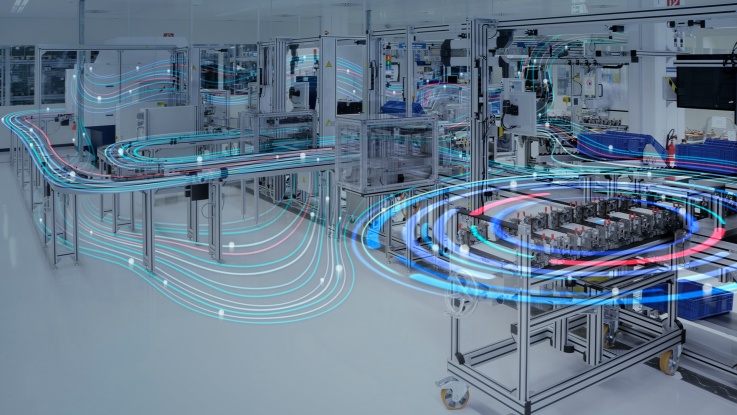

Our portfolio of innovative, flexible and complete production solutions enables battery manufacturers to get to market faster through cross-technology production systems that target key manufacturing steps, such as electrode and cell production, battery module and pack assembly stations and end-of-line testing.

Industry-leading portfolio to supercharge battery production

ctrlX AUTOMATION: Automation without limits

Battery manufacturing needs agile, adaptive production platforms able to change as battery innovation continues. ctrlX AUTOMATION revolutionizes how the industry approaches automation platforms, making them as easy as a smartphone to configure and use, through:

- A Linux real-time operating system

- App-based programming technology

- Consistent open standards

- Web-based engineering

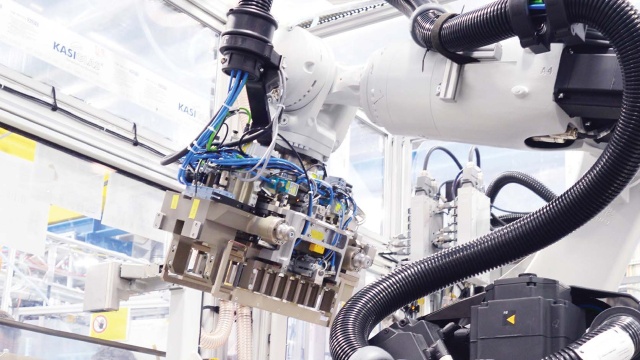

Smart MechatroniX: Plug-and-produce platforms

With battery demand constantly growing, manufacturers need production tools ready to operate out of the box. Our plug-and-produce Smart MechatroniX systems combine proven linear motion components with smart, easy-to-program controls and user-friendly engineering tools to provide:

- Accelerated engineering, commissioning and time to market

- More transparent, efficient and reliable production

- High operating performance and sustainability through permanent updating

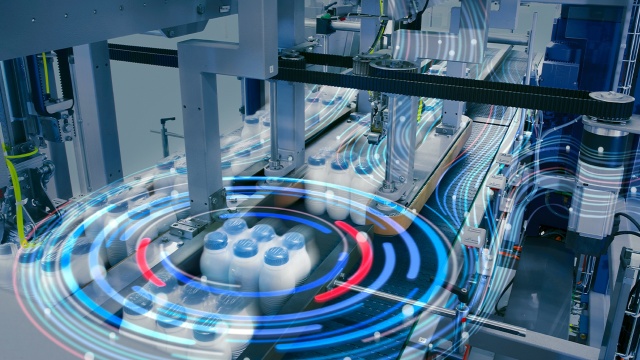

Conveyors and material transport: Boost your production

Battery manufacturers are constantly challenged to move a wide range of loads through complex production steps. Bosch Rexroth conveyors and transport systems are ready to meet multiple material movement challenges, combining innovation with efficiency and flexibility. With ActiveMover, VarioFlow plus and TS conveyors, you can count on:

- The industry’s widest range of transport technologies to make it easier to select the best platform

- Robust components and innovative technology that ensure high reliability at low maintenance costs

- Linear motor-based transport systems that support ultra-precise endpoints and accelerations up to 4g

- Consistent modular design combined with our MTpro tool to speed up planning and allow easy upgrades

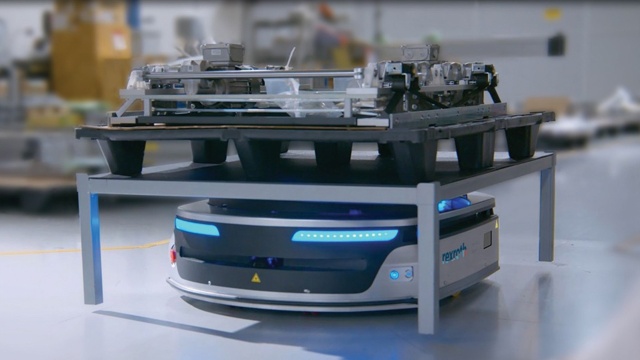

Autonomous mobile robots: Improve manufacturing intralogistics

To accelerate battery production and speed to market, moving materials from warehouse to storage to production must be as efficient as possible. Bosch Rexroth’s expanding portfolio of autonomous mobile robots (AMRs) are designed to help improve material movement efficiency and worker safety in intralogistics applications without additional infrastructure. Our MP1000R AMR portfolio includes:

- Compact design makes it ideal for tight turning spaces

- Max payload of 1000 kilograms

- 360-degree obstacle detection and front-and-rear anti-collision bumpers