Products

OverviewIndustries

OverviewService

OverviewCompany

OverviewProduct groups

OverviewEngineering

OvervieweConfigurators and Tools

OverviewManufacturing automation solutions

OverviewPartner

OverviewJob opportunities

Overview

Connectivity, vehicle and data management from a single source: electric pioneer AllTrec is taking its universal equipment carriers to the next level of digitalization with the help of a complete telematics solution from Bosch Rexroth.

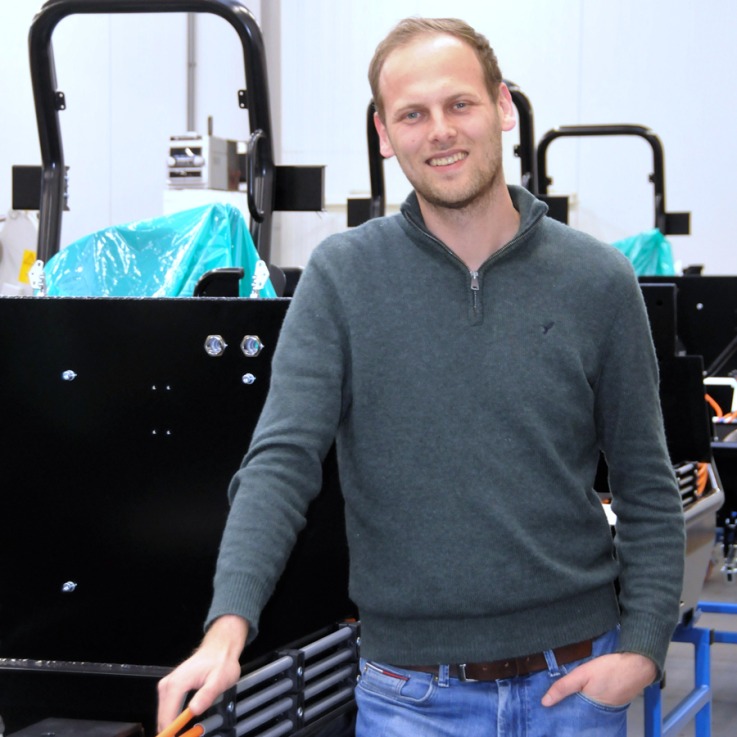

Around six years ago, Frank van de Staak foresaw what is now obvious: the electrification of the powertrain in the automotive industry is also changing the gardening and landscaping sector. The R&D engineer seized the opportunity and developed the world's first all-electric equipment carrier. Following the launch of the compact 4810T model, the Dutch company has gone one step further with the no less innovative 8015F. Not only in terms of its versatility, but also on the subject of telematics and connectivity, which AllTrec consistently develops with the help of the complete solution BODAS Connect All-in-one Connectivity.

The zero-emission implement carrier with driver's cab is aimed at municipal and commercial users who want to perform a wide range of tasks cost-effectively in all four seasons. From mowing, hedge trimming and weed control to sweeping, leaf blowing, snow removal and gritting. To ensure this universality, all AllTrec models can be equipped with a variety of attachments. The climate-friendly and quiet operation also allows trouble-free work in environmental zones or quiet areas. The safe LiFePO4 batteries are charged overnight, so the machine can start up again in the morning with 100 percent electric power.

AllTrec models can be equipped with a variety of attachments

Frank van de Staak is convinced that his users are increasingly looking for seamless digital connectivity for their machines, and that service and development will also benefit from an IoT solution. "Innovation is a very important part of our business, data is the fuel," clarifies the AllTrec founder. "Telematically captured vehicle data enables us to continuously improve our machines and optimize operations. For maximum profitability, we also need reliable over-the-air services and fast troubleshooting remotely. In addition, we want to provide our service partners, dealers and customers with targeted solutions for using the data in the future."

Future-proof basis of the modular BODAS Connect ecosystem: The robust and processor-based Rexroth Connectivity Unit (RCU) with open-source Linux operating system.

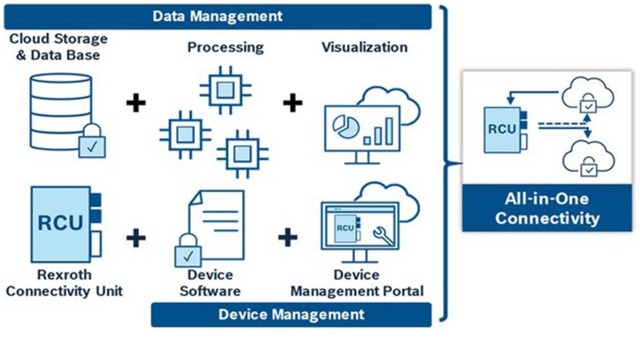

In view of the complex telematics requirements, the necessary off-highway expertise and in regard to a short time-to-market, AllTrec decided to work with existing mobile electronics and hydraulics partner Bosch Rexroth. The chosen solution All-in-One Connectivity combines the BODAS Connect building blocks Device Management and Data Management to a secure end-to-end solution that can be integrated and extended with minimal development effort. The Linux-based telematics unit RCU is used for the collection and efficient transmission of vehicle data. Robust hardware, open standards and a layered software architecture provide AllTrec with a high level of future security.

First, with the help of Bosch Rexroth, AllTrec implemented over-the-air services to update the extensive software on their machines, as well as essential service functions such as remote diagnostics and configuration. "This way, we can not only transmit updates to the RC control units and the RCU telematics unit, but also change parameters in the field or check service actions by dealers," explains Jaap van Norel, product manager at AllTrec. "Since the project started at the end of 2021, we have already been able to equip 30 machines, with around 100 more planned for this year. Demand is high, we want to grow continuously and for this we need a solid device management system suitable for large-scale use, which we have also found at Bosch Rexroth."

Bosch Rexroth also proved its worth as a technology partner before the introduction of the telematics solution. The central control unit BODAS RC10-10 is responsible for all CAN-based subsystems such as the inverters, battery management or power steering. In addition, AllTrec also uses a compact hydraulic block with double-acting cylinders to lift and steer the electrically operated attachments. On the software side, Bosch Rexroth developers contributed to the automatic recognition of the attachments, which enables their automatic parameterization and setup. From the sensor technology area, AllTrec obtains the PR4 pressure sensor and the MM7.10 inertial sensor. In future, the inertial sensor will be used to record various machine states, traction changes or the position of the vehicle. This is relevant for work safety, among other things, as excessive slopes when mowing on a slope can be prevented by a timely warning, for example. Jaap van Norel also finds the new BODAS DI5 display interesting for the next model generation. This is because the HMI can communicate directly with the RC control system and peripheral devices such as joysticks, etc., and can also be updated over-the-air via the RCU.

With the help of the complete telematics package BODAS Connect All-in-One Connectivity, AllTrec has already implemented the first milestones. Connectivity with the vehicles has been established, and all desired raw data is reliably collected and transferred to the cloud. Device management has also been implemented, and now it's time to move on to solution development in the context of data management. "With the help of ready-made templates and drag-and-drop building blocks, we want to gradually develop customized dashboards," says AllTrec CEO Van de Staak. "Both for our own service and development department and for dealers, service partners and users."

Watch the video: BODAS Connect All-In-One Connectivity explained

BODAS Connect All-in-One Connectivity: The complete telematics package from Bosch Rexroth for the rapid setup of scalable end-to-end solutions

In terms of possible use cases, it is conceivable, for example, to record certain operating states in order to draw conclusions about energy consumption, for such things as the mowing frequency or the power consumption of the engines. From a service perspective, the roadmap also envisages predictive maintenance for engines. Here, too, energy consumption serves as an indicator to generate a maintenance order in good time before an impending failure and to order the necessary spare parts. For end customers, Frank van de Staak and Jaap van Norel can also imagine many digital services to maximize availability, productivity and efficiency. For example, a request to resharpen the blades in the mowers could be issued based on the energy data collected.

The data could also help vehicle users to perform their contractually agreed tasks even more efficiently or to provide evidence of them. For example, the position and operating data could be used to determine the optimum mowing frequency and avoid inspection trips and unnecessary transport costs. Geo Fencing could also be used to prevent driving and working in protected or critical areas.

This saves travel costs and avoids productivity losses. Recently, a Swiss customer was helped remotely within half an hour. Without OTA, the transport to the dealer would have meant a two-day delay.”

Frank van de Staak, Founder and R&D FPS Alltrec

Find out more about professional Data Management: Download Whitepaper here

Frank van de Staak

Frank van de Staak's initial experiences have been very positive. "The RCUs delivered preconfigured by Bosch Rexroth are immediately ready for operation after installation. The OTA services work reliably and enable us to quickly solve any problems that arise. This saves travel costs and avoids productivity losses. Recently, a Swiss customer was helped remotely within half an hour. Without OTA, the transport to the dealer would have meant a two-day delay.”

The AllTrec team also has high hopes for the newly introduced Inertial Sensor. "The inertial sensor is crucial for future services," emphasizes Frank van de Staak. "If we can further improve the user-friendliness of the traction system, we can reliably avoid overload conditions and further increase ride comfort and efficiency."

Zero emissions, all-wheel drive, a comfortable cab and IoT for next-level aftersales functions: The AllTrec 8015F is universally applicable and highly connected. (Photo: AllTrec)

As part of the new fleet management program, AllTrec can now update vehicle software in the field, roll out new features remotely, and manage the fleet efficiently. "Although we are still a relatively small company, we feel optimally looked after and supported," sums up Frank van de Staak. "With the help of Bosch Rexroth, we have laid the foundation for further development and equipping more series models."

Jaap van Norel agrees: "We have relied on the right solution to further realize our vision and take our machines to the next level. Our customers are excited about the new transparency and the potential of the Internet of Things that we are unleashing together with Bosch Rexroth."

Find out more about BODAS Connect and test it for free

Author: Olaf Marshall

Position: Communications Manager Business Unit Mobile Hydraulics