Select your location

Bosch Rexroth around the world

Asia & Pacific

Europe

Sustainability at Bosch Rexroth – Driving a more sustainable future forward

As part of the Bosch Group, sustainability is firmly anchored in our values. We are committed to contributing to a world that future generations can thrive in, and we believe that innovative technology plays a key role in achieving this goal.

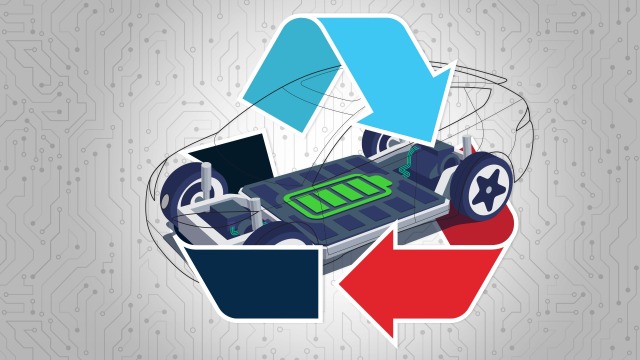

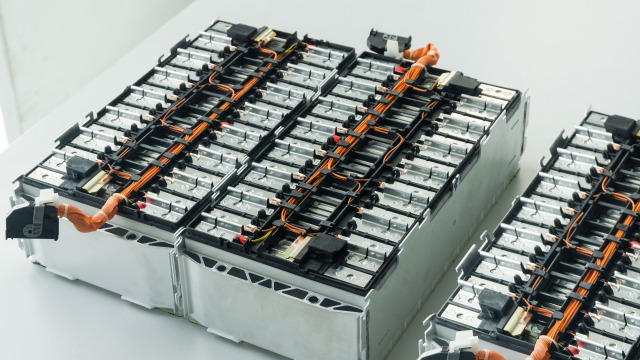

We take a comprehensive approach to implementing sustainable practices/policies throughout the entire product life cycle, supporting our customers in enhancing sustainability in factory automation, industrial hydraulics, and mobile machinery. Our expertise in intelligent products, solutions, and applications enables us to assist you in reaching your sustainability goals. Furthermore, we actively seek collaboration with you to unlock applications driven by energy transformation. Read on to witness how innovative technology can make a difference.

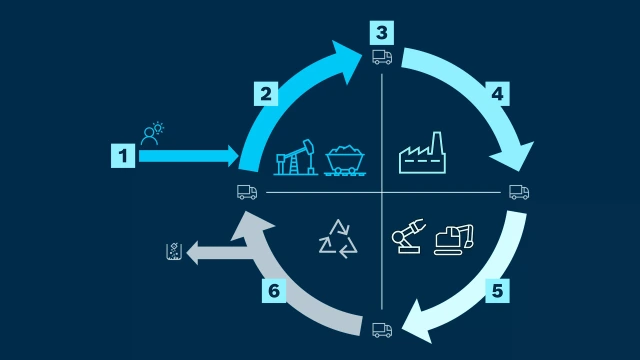

Follow the journey along the product lifecycle

We strive to implement sustainable practices/policies throughout the entire product life cycle. From thoughtful design and responsible purchasing to efficient logistics, production, and innovative recycling or remanufacturing solutions, we are actively taking steps to reduce our environmental impact. By embracing a circular perspective, we can identify and address key areas for improvement across our products' entire life cycle. With this approach, we also aim to support our customers in successfully transitioning to a circular economy, reducing their carbon footprint over the whole value chain.

Sustainability report of Bosch Group:

Please find further information on sustainability within the Bosch Group:

https://www.bosch.com/sustainability/#sustainability-report