Industries

Overview- Agriculture and Forestry

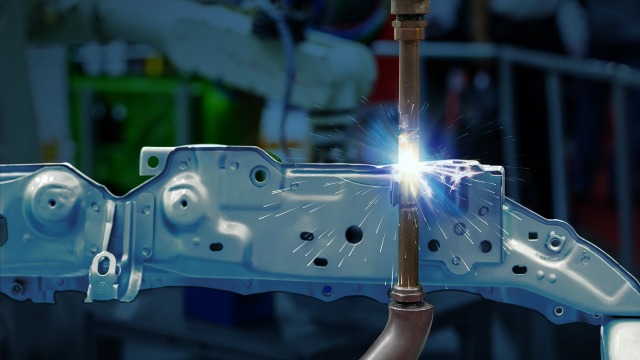

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Consumer goods

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

Service

OverviewProduct groups

OverviewEngineering

OvervieweConfigurators and Tools

Overview

United Kingdom

English