Select your location

Bosch Rexroth around the world

Asia & Pacific

Europe

The trend towards the networking of machines and IT for the Internet of Things (IoT) has been gaining momentum for years, enabling data to be exchanged, monitored and analyzed. However, when artificial intelligence is brought into the equation, a whole new world of possibilities emerges. Find out what it means for the manufacturing industry and how you can start to reap the rewards.

Artificial intelligence (AI) refers to algorithms with which IT systems independently learn from experience, understand and act. By combining AI with IoT to create the Artificial Intelligence of Things (AIoT), the result is a powerful combination that will dramatically shape the world of automation.

The AIoT has the potential to automate activities previously carried out by people and to significantly increase the productivity of machines and factories. With AI, machines will better understand their environment and act accordingly – in short, making the leap from being reactive to being proactive.

Özge Karadag

Mover for AIoT

One of the benefits of the Internet of Things is that it enables vast quantities of data to be gathered from connected machines and systems. However, having huge quantities of data is only a benefit if the data is being used effectively. A report from Forrester notes that up to 73% of data within an enterprise goes unused.

The infusion of AI into IoT systems addresses this issue and ensures that the data is put to good use. AI can translate the data into actionable insights, make proactive decisions and enable automated machines and systems to become more sophisticated in the way they behave. They’ll be able to take on tasks that previously were the sole domain of people – and in so doing will make factories far more productive and efficient.

Özge Karadag

Mover for AIoT

When the topic of artificial intelligence arises, concerns around trust are often first and foremost in people’s minds. Is it safe? How will it affect the role of people? What if we lose control? For the AIoT to be widely adopted, these concerns clearly need to be addressed.

Firstly, it’s worth clarifying what type of AI we’re talking about. Broadly speaking, there are two forms of AI: “strong AI” and “weak AI” (also known as “narrow AI”). Strong AI is an intelligence that’s equal to or even superior to human intelligence. It’s the stuff of Hollywood films and has not yet been achieved. Weak AI, on the other hand, is already widespread and used in various ways in our day-to-day lives – such as in voice recognition systems, for sign recognition in cars, and in personalized online advertising. In production, “weak artificial intelligence” can learn from process information from machines and systems, optimize processes and predict future events such as component failures.

When we consider it in this context, there’s no doubt that AI, technology and machines will play an important part in automated production, but people will still be at the heart of the factory and control must remain firmly in human hands. We see the AIoT as complimentary to the human workforce, working alongside people and taking on the tasks that they find difficult, such as calculating complex data. Augmented intelligence – a human-centered partnership model where people and AI work together – will empower people’s skills. Tasks involving creativity and perception, however, are still very much the domain of people.

When businesses purchase hardware, they usually have clear quality criteria that must be met – performance characteristics, the range of functions and the absence of faults are some examples. Similarly, purchasers and users of AIoT solutions must feel confident that strict criteria are being met.

In 2020 we adopted the AI Code. As a result, our AIoT solutions already meet these digital trust criteria:

The wider Bosch Group has also recognized this industry-wide challenge and is a co-initiator of the Digital Trust Forum, a global initiative that will develop and define the framework for trustworthy digital AIoT solutions.

Özge Karadag

Mover for AIoT

Sometimes the AIoT can feel overwhelming and it’s difficult to know where to begin – especially for smaller companies that don’t have big budgets or in-house specialists. But the good news is that the AIoT is not just the privilege of large companies. Nor does it have to mean huge investment or excessive changes to your existing set-up. By implementing AIoT solutions in small, incremental steps, even SMEs can start to reap the rewards.

You don’t need to embed AI in every business process and function to benefit from it. You could start by concentrating on a specific area, such as predictive maintenance and corrective measures, in order to increase efficiency and reduce unplanned downtime. Or you could choose from our selection of AIoT products and solutions that can be easily incorporated into your existing factory infrastructure. The key is not to be overwhelmed by the enormity of the possibilities – after all, it’s better to start small than not to start at all.

At Bosch Rexroth, we’ve been providing added value to our customers by connecting intelligent products and services as part of the IoT for years. The addition of AI closes the value creation cycle. The huge quantity of data that’s generated from these intelligent products as they interact with people and machines is gathered and evaluated by artificial intelligence. This information is then fed into our product development in order to improve our products and services on an ongoing basis.

We’re already bringing the benefits of AI to our customers in a number of our solutions. Broadly speaking, these fall into three categories:

Expert systems help people to solve complex problems by coming up with recommendations from a knowledge base. As well as creating the knowledge base, improving it, processing it and making it comprehensible to the user, it also draws further conclusions. An example of this is our hydraulics commissioning wizards, which guide technicians through the commissioning process and suggest suitable parameters. Another is the ctrlX Configurator, an expert system that helps engineers design and configure complete system solutions in the optimum manner.

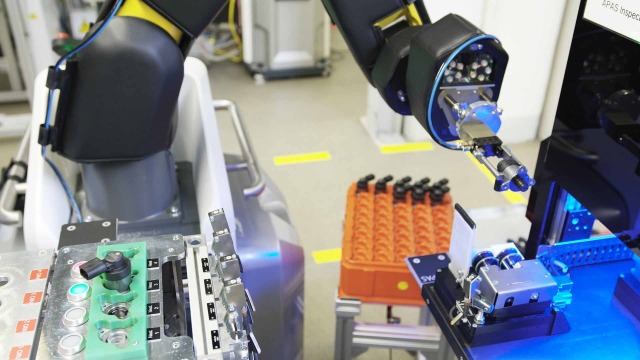

Symbolic artificial intelligence (machine learning) assumes that knowledge is represented by symbols. Machines interpret images or language on the basis of algorithms and logical relationships for expert systems. The algorithms compare these rule-based relationships with new information and learn from this. An example of this type of technology is our APAS inspector, a production assistant for automatic visual inspection. Thanks to its learning image processing software, it can be “retrained” at any time and even operators with no specific knowledge of image processing can optimize and adjust the checking parameters.

Neural artificial intelligence (deep learning) is based on the structures of the brain and the way in which nerve cells work, with knowledge segmented into hierarchically linked layers. Our Smart Item Picking system solution is an example: with the help of AI, the software recognizes the products to be grasped and works out how to pick them up smoothly.

In the field of predictive analytics, CytroConnect Predict carries out a predictive analysis of a hydraulic system on the basis of self-learning algorithms. The system is equipped with sensors from which data is collected and evaluated with the help of artificial intelligence. Issues can be detected before they result in a breakdown, maximizing the availability of the system.

As a data specialist, Özge understands the incredible potential of artificial intelligence and the Internet of Things. In her role as a Program Manager in Bosch Rexroth’s Online Customer Support Team, she experiences the value of meaningful data that comes from our customers on a daily basis. As well as having a personal and professional interest in this topic, she intends to be a strong voice in the field of AIoT.