Products

OverviewIndustries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Consumer goods

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

Service

OverviewCompany

OverviewBuy

OverviewProduct groups

OverviewEngineering

OvervieweConfigurators and Tools

OverviewJob opportunities

OverviewEDI (Electronic Data Interchange)

Overview

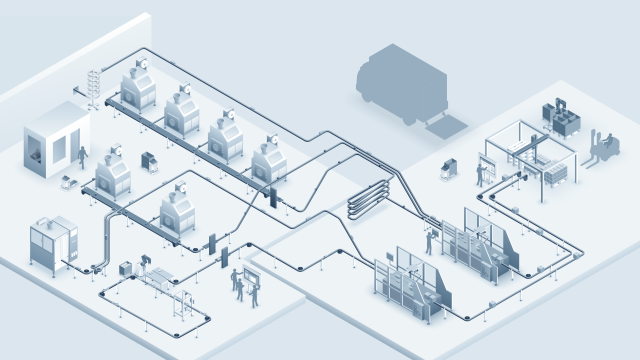

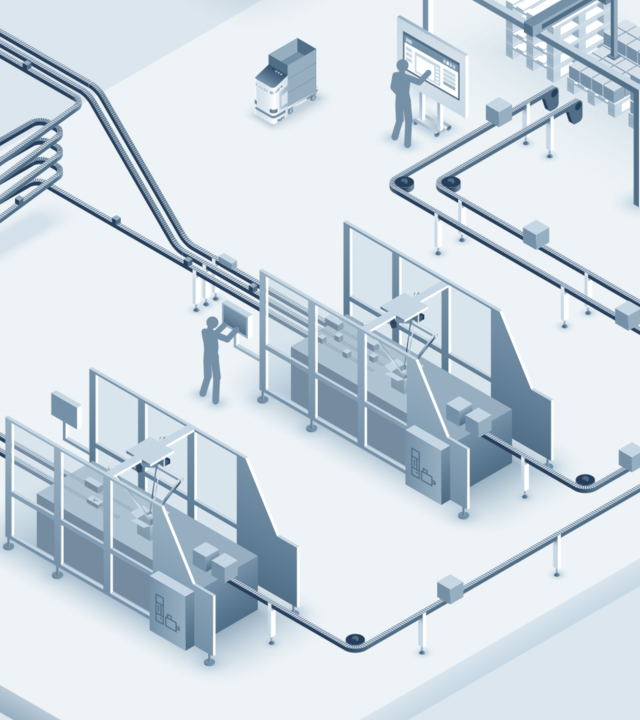

Faster moving consumer goods with solutions from Bosch Rexroth

Quicker cycle times, increased efficiency and higher productivity along the entire value chain.

One provider. Reduced costs.

Increased productivity.

The market places very special demands on the FMCG industry: Increasing cycle times, resource efficiency and innovation are more important here than in any other sector. In order to maintain product quality and precision at the same time as being able to react flexibly to individual customer requirements, Bosch Rexroth is at your side as your technology partner. With our automation solutions, we help you to optimize and digitalize your entire value steam.

And with our innovative products and services, we offer you real added value:

Flexible and reconfigurable solutions, energy-efficient and sustainable

- Transparency within your processes thanks to digital excellence

- Consistent architecture and open interfaces

- Full connectivity across all devices

- Connection to MES or ERP systems

- Excellent service worldwide

Value stream

Reference projects

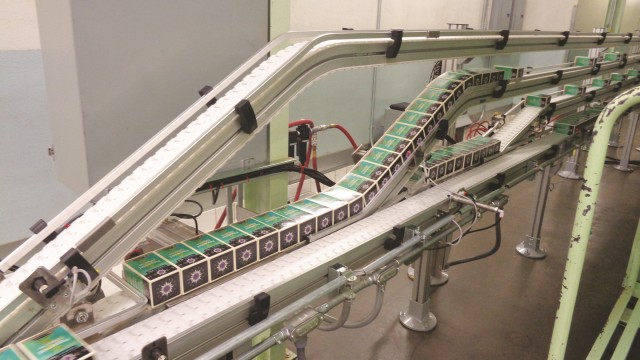

Stacking assembly with hygienic conveyor system

Customer

Yamamotoyama of America tea manufacturer

Challenge

Assembling groups of twelve cartons in a limited space precisely and without errors in the cartoner, taking care to protect the surface of the carton.

Get to know the processes

Solution

VarioFlow plus chain conveyor system with a smooth chain surface.

View solutions

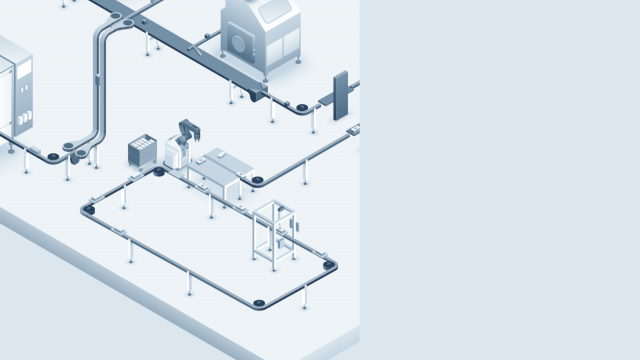

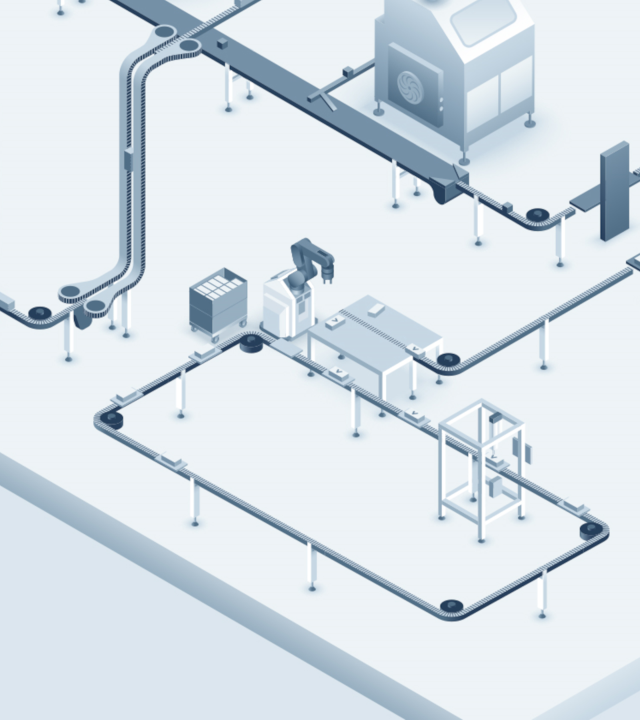

Collaborative robot for automating co-packing processes

Customer

Bosch Ansbach plant, Germany

Challenge

Supporting, assisting and automating routine processes in EPS control unit production.

Get to know the processes

Solution

Variable automation with APAS assistant, flexible configuration of the human-machine mix.

View solutions

Greater flexibility in production

Customer

CAMA Group, Italy

Challenge

Developing an end-of-line packaging machine for multiple robots that maintains speed and accuracy while reducing the overall size and cost.

Get to know the processes

Solution

The functions of multiple robots are integrated seamlessly into a system, as a result of which it is no longer necessary to have a number of communication interfaces between the individual robot control systems.

View solutions

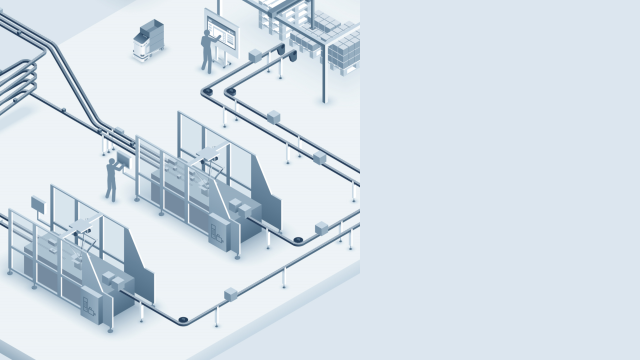

Data collection made easy

Customer

Bosch Thermotechnik, Germany

Challenge

Transparent data preparation and analysis for trouble-free dispatching in warehouse logistics at Bosch Thermotechnik.

Get to know the processes

Solution

ACTIVE Cockpit interactive communication platform.

View solutions

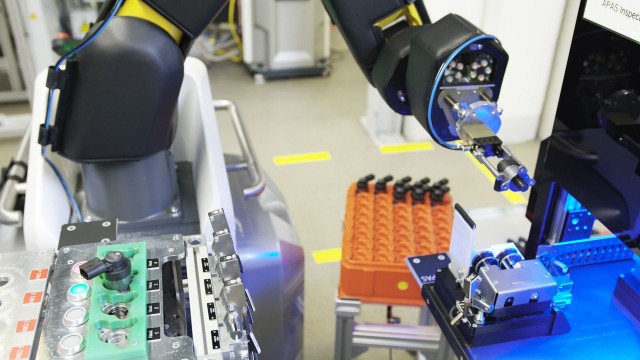

Fully automated quality checks

Customer

Bosch Feuerbach plant, Germany

Challenge

Relieving the burden on employees and ensuring consistently high quality.

Get to know the processes

Solution

Combination of APAS assistant mobile and APAS inspector for fully automatic quality assurance.

View solutions