Products

OverviewIndustries

Overview- Agriculture and Forestry

- Automotive

- Battery production

- Chemical processing

- Construction and Infrastructure

- Consumer goods

- Energy and Utilities

- Healthcare

- Hydrogen

- Logistics and Transport

- Materials and Resources

- Pharmaceutics

- Recycling and Waste handling

- Renewable energies

- Semiconductors and Electronics

- Testing Technology

Service

OverviewCompany

OverviewBuy

OverviewProduct groups

OverviewEngineering

OvervieweConfigurators and Tools

OverviewJob opportunities

OverviewEDI (Electronic Data Interchange)

Overview

FOCUS ON THE VALUE STREAM

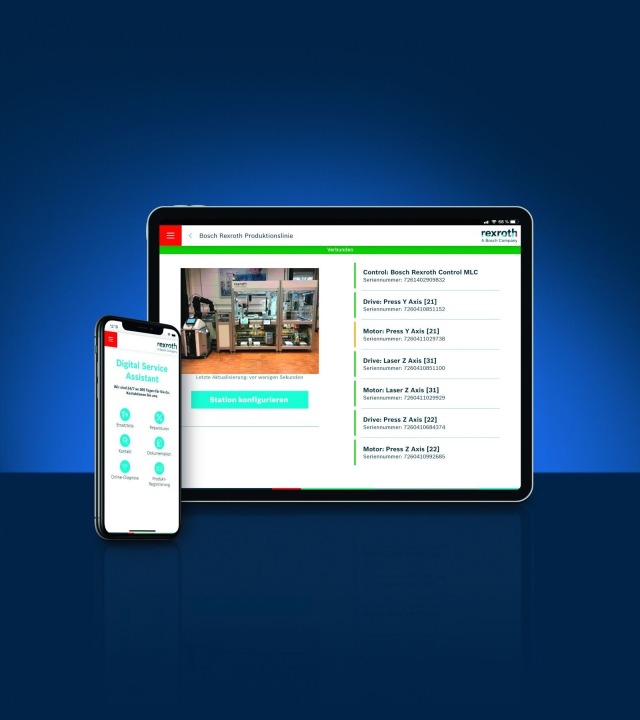

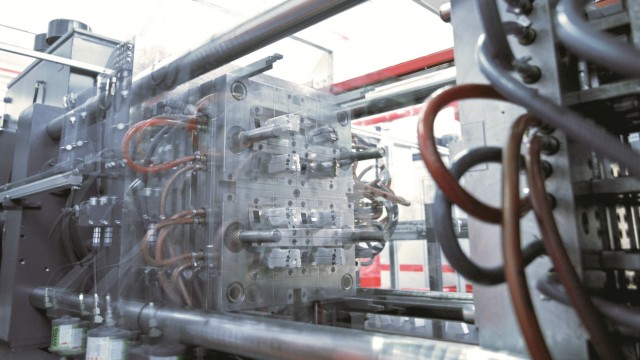

We understand the specific requirements that the market places on you. As a technology partner for automation solutions, Bosch Rexroth supports you and helps you to optimize your entire production value stream. With our global production network, we’re a key user and provider of innovative products and services which offer genuine added value in automation. We share our application experience to support you on the way to the Smart Factory. Rethinking production: Try our products and services yourself.